Closed-Loop vs. Open-Loop: Which Servo Setup Is Right for Your Application?

Servo systems move the world’s production lines, but not all servo setups are created equal. The fundamental split between closed-loop and open-loop control shapes everything from initial costs to long-term reliability. Getting this choice right saves money and prevents downstream problems — getting it wrong does the opposite. If you’re making the choice between open- vs. closed-loop servo systems, here’s what you need to know to make the best choice.

Open-loop systems: Simple and cost-effective

Open-loop servo systems operate without feedback mechanisms. The controller sends commands to the motor, trusting that the intended motion occurs. This straightforward approach eliminates the need for encoders, resolvers, or other position-sensing devices. Open-loop systems work best in applications with predictable loads and minimal external disturbances.

The primary advantage of open-loop systems is their low-cost setup and maintenance. Manufacturing facilities can implement these setups at significantly lower price points compared to closed-loop alternatives. The reduced component count also means fewer potential failure points and simplified maintenance over time.

Real-world example: Assembly line operations, pick-and-place machines, and basic positioning tasks often function well with this approach. Stepper motors also use open-loop control in applications like 3D printers, CNC machines with light cutting loads, and conveyor systems.

Closed-loop systems: Accuracy through feedback

Closed-loop servo systems continuously monitor actual position and compare it to commanded position. This feedback loop enables real-time corrections, for precise motion control even under varying conditions.

When position accuracy is paramount, it’s difficult to beat closed-loop control. These systems can detect and correct for load variations, mechanical wear, and external disturbances. The feedback mechanism allows for much tighter tolerances than open-loop alternatives. The trade-off comes in complexity and cost. Closed-loop systems require additional hardware, more sophisticated controllers, and increased setup time. Plus, the feedback devices themselves need regular calibration and maintenance.

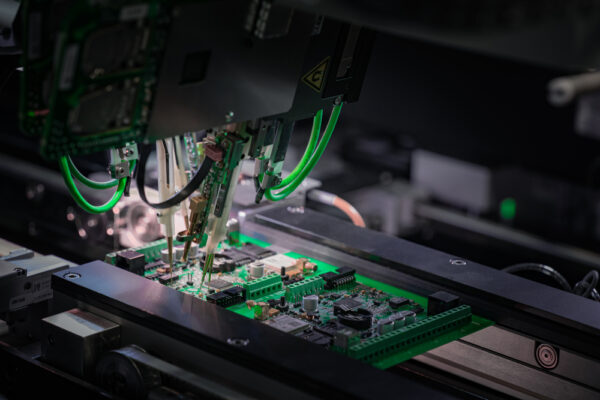

Real-world example: Servo motors paired with encoders or resolvers create closed-loop systems capable of exceptional precision. High-speed machining centers, robotic arms, and precision assembly equipment rely on this level of control.

4 questions to help you choose the right servo setup

Application requirements drive the decision between open-loop and closed-loop systems. These four questions will help narrow down the best choice for any manufacturing application:

- What type of loads will the system handle? Constant, predictable loads favor open-loop systems. Variable or heavy loads benefit from closed-loop feedback. A packaging machine moving lightweight products might work well with open-loop control, but a heavy-duty press requires closed-loop precision.

- How fast does the system need to operate? High-speed applications often need closed-loop systems to maintain accuracy during rapid acceleration and deceleration cycles. Low-speed operations can often achieve adequate performance with open-loop control.

- What environmental challenges exist? Vibration, temperature changes, and mechanical wear all affect system performance. Closed-loop systems adapt to these conditions automatically, while open-loop systems may require manual adjustments or periodic recalibration.

- What’s the budget reality? Open-loop systems offer lower initial costs and reduced maintenance expenses. Closed-loop systems require higher upfront investment but may provide better long-term value through improved productivity and reduced waste.

Making the final call

Both servo control methods have earned their place in modern manufacturing. Open-loop systems excel in cost-sensitive applications with predictable operating conditions. Closed-loop systems shine where precision and adaptability are critical.

The best choice depends on balancing performance requirements against cost considerations. Many facilities use both approaches, selecting the appropriate system for each specific application. This mixed strategy can have far-reaching benefits across factory operations. The key is making sure every system is properly installed, well-serviced, and intentionally calibrated.