Backlash in Servo Systems Isn’t Always Mechanical

A servo system starts overshooting positions, oscillating when it should hold steady, and losing repeatability fast. Most technicians reach for the mechanical checklist first: worn gears, loose couplings, failing bearings. The symptoms certainly point that direction, since position errors feel like mechanical slop and erratic behavior suggests worn components.

But electrical faults create identical symptoms that can fool even experienced technicians. A failing encoder can produce the same positioning errors as a worn gearbox, while control loop problems cause behavior that mimics mechanical backlash perfectly. Without proper electrical testing, the symptoms become indistinguishable, and chasing mechanical problems wastes valuable time when the real issue might be entirely electrical.

Encoder problems that fool you into thinking it’s mechanical

Position feedback drives servo accuracy, and when encoders fail, the servo controller gets bad data and makes bad decisions. Optical encoders are particularly vulnerable because they rely on precise light transmission through tiny slots or patterns, where even microscopic contamination can disrupt the signal enough to create positioning errors that feel like worn gearboxes. The symptoms look like mechanical backlash: overshoot, poor positioning, and erratic behavior.

Common encoder faults that mimic mechanical issues:

- Contaminated optical discs from dust, oil, or machining debris

- Loose encoder mounting hardware allowing position drift

- Electromagnetic interference from nearby high-power equipment

- Degraded encoder cables with broken conductors or damaged shielding

- Connector corrosion causing intermittent signal loss

- Wrong encoder resolution settings in the drive parameters

Control loop issues that mimic backlash

Servo drives rely on precise control algorithms to maintain position, but when these parameters drift out of spec, the system exhibits the same symptoms as worn mechanical components. The challenge is that these electrical problems develop gradually as temperatures change, components age, or system loading varies throughout the day. What worked perfectly during commissioning might create instability months later, making technicians suspect mechanical wear when the real culprit is electrical drift.

Signs your control loop needs attention:

- Position overshoot from excessive proportional gain settings

- Hunting behavior caused by too much integral gain

- High-frequency oscillations from incorrect derivative gain

- Network delays affecting real-time position feedback

- Motor inertia settings that don’t match the actual load

- Temperature compensation parameters set incorrectly

Power supply and grounding problems

Clean, stable power is essential for servo accuracy, and voltage fluctuations affect servo response in ways that perfectly mimic mechanical wear. Power quality issues often worsen during peak production hours when multiple systems compete for clean power, so a servo that tracks perfectly during light loads might exhibit apparent backlash when the facility’s electrical demand peaks. Poor grounding introduces noise into the control system that destabilizes positioning in patterns that feel mechanical.

Power-related causes of apparent mechanical backlash:

- DC bus voltage ripple creating inconsistent torque output

- Ground loops between drive, motor, and encoder systems

- Voltage sags during high-load operation

- Temperature drift in drive components affecting precision

- Inadequate power supply capacity for peak demands

- Missing or degraded surge protection devices

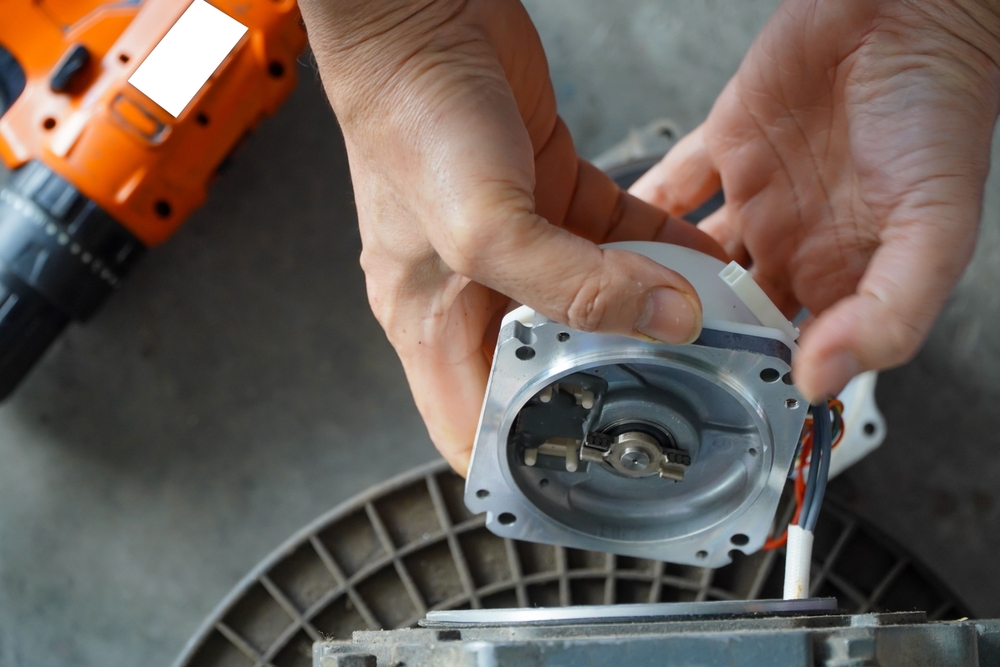

Electrical diagnosis prevents unnecessary teardowns

When electrical faults masquerade as mechanical problems, the wrong diagnosis leads to unnecessary repairs and extended downtime. Before pulling apart a servo system, check the electrical side first. Scope the encoder signals for noise or dropouts, verify control parameters match the motor specifications, and test power supply stability under load.

These checks take minutes but can save hours of mechanical inspection and prevent unnecessary downtime caused by chasing the wrong problem.