Can You Automate and Still Retain Your Workforce?

If you approach it carefully, automation can be a win-win for everyone, especially maintenance supervisors, production managers, and plant supervisors. The caveat is that there is no one-size-fits-all solution because decisions regarding what to automate and when to automate them are not so simple. To maximize benefits, you need to organize a concerted team effort.

Automation benefits

For plant, production, and maintenance supervisors, automation offers a number of key benefits.

- Enhance profitability

- Improve employee work conditions

- Bolster manufacturing industry position

To bring these automation benefits to fruition, you should answer the following questions for your company:

How will automation in one area impact business overall?

How will automation in one area impact business overall?

“The transportation equipment, computers and electronics, electrical equipment, and machinery industries are expected to account for around 75 percent of advanced robotics installations through 2025,” according to a BSG Research report.

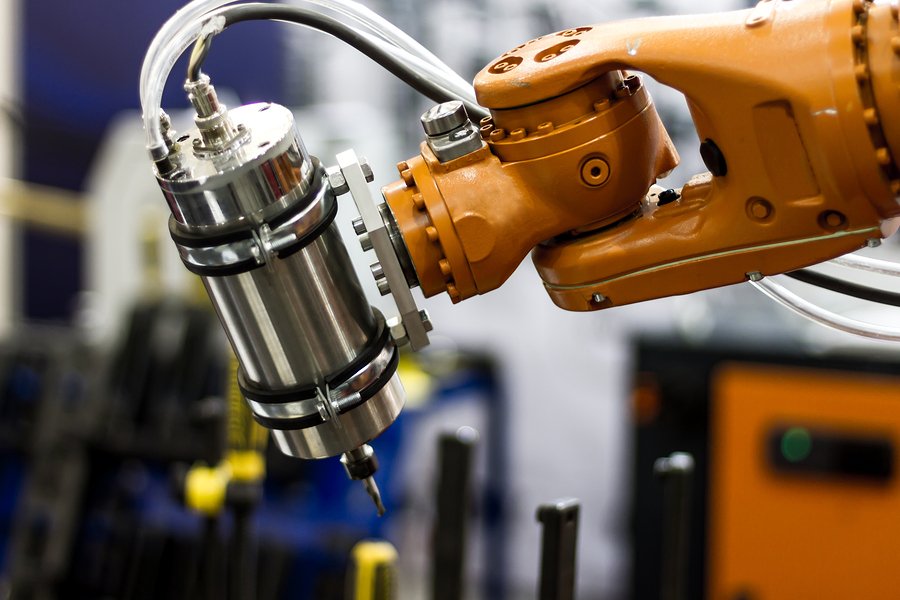

Automation sets the stage for additional high-tech equipment rollouts. Manufacturing experts argue that automated systems don’t necessarily need full-service robots to be effective. Instead, some functions and features make a system appropriate for robots.

Do you have reliable staff you can cross-train to work elsewhere where skills are short?

As you know, the manufacturing industry in the U.S. is facing a skills shortage over the next eight years. The good news is that you don’t necessarily have to trim your workforce after increasing automation. Instead, utilize their expertise in other areas and consider cross-training for future needs and skills shortages.

According to the BSG Research report, regarding a projected increase in industrial robotics, “As a result, the total cost of manufacturing labor in 2025 could be 16 percent lower, on average, in the world’s 25 largest goods-exporting nations than they would be otherwise.” These expectations dovetail with the strategy of cross-training employees to expand their knowledge of robotics or other areas on the production line.

According to the BSG Research report, regarding a projected increase in industrial robotics, “As a result, the total cost of manufacturing labor in 2025 could be 16 percent lower, on average, in the world’s 25 largest goods-exporting nations than they would be otherwise.” These expectations dovetail with the strategy of cross-training employees to expand their knowledge of robotics or other areas on the production line.

Automation is certainly not easy, but researchers predict robots will cost less, allowing for a productivity increase of up to 30% by 2025. What does this mean for you and your manufacturing business? Adding a robotic arm to your production processes or another type of automation can keep you competitive and on the cutting edge of the industry.

In need of a repair? At Global Electronic Services, we service equipment from some of the biggest original equipment manufacturers in the business and guarantee our work with an 18-month in-service warranty because we’ll be confident we’ve fixed your machine problem.

Contact us at [ab_phone] for all your industrial electronic, servo motor, AC or DC motor, hydraulic, or pneumatic needs.