Augmented Reality is the Key to Upskilling Manufacturing Employees

Manufacturing is entering a pivotal time. Reshoring has become a movement and manufacturing innovation is on the rise. Industrial Internet of Things (IIoT) and other digital technologies are becoming more accessible. The ingredients for major manufacturing resurgence are all present — there’s just one thing missing: talent. The skills gap in manufacturing has never been more prevalent, at a time when qualified workers have never been more important.

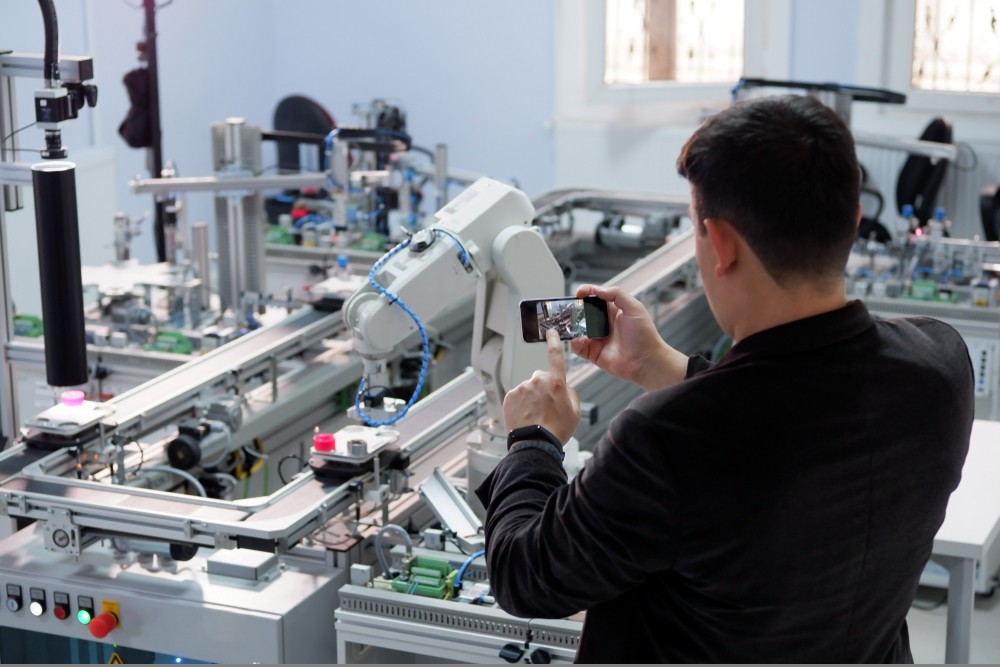

While there’s still a lot to be done for institutional STEM (science, technology, engineering, mathematics) education, manufacturers need to start thinking seriously about how to rapidly modernize their existing workforce. How can you take the veteran employees you have — those who understand the operation and nuances of your factory — and imbue them with new skills and next-generation knowledge? The answer rests in augmented reality (AR).

AR as the foundation for training

Upskilling current employees who already understand factory operations has twofold benefits. First, it’s a reinvestment in talent you already have, which means less time spent teaching them foundational skills for a job they already know. Second, it’s empowering for workers and gives them career mobility within your company: higher earning potential, upward advancement prospects, and job security.

As the future of manufacturing becomes increasingly digital, AR serves as a natural bridge from the skills your employees already have to the technologies they need to master. It’s a concept called “Skill-XR.” According to experts who coined the term, “the “X” in “Skill-XR” stands for a range of technologies that includes augmented reality (AR), virtual reality (VR), and extended reality (XR).”

Bringing the benefits of AR to factory floors

AR as a training method offers broad benefits. Not only does it empower employees to upskill in a meaningful way, it allows them to do it quickly, safely, and with the support they need. AR is quickly redefining training programs in factories across the country because it:

- Provides safer training, especially in hostile environments or around hazardous materials

- Streamlines training opportunities with data-driven feedback

- Is ideal for maintenance and machine servicing

- Offers superior support when training on complex mechanisms and systems

- Provides real-time, comprehensive feedback and guidance

Think about AR goggles or tablet applications. Registering real-time actions performed by the worker, AR apps deliver the above benefits, geared toward improving the teaching experience. Also, this training is self-directed, which saves significant time and man hours.

AR gains traction in the COVID-19 era

Another reason Skill-XR, and AR in particular, have gained traction recently is due to COVID-19. Instead of person-to-person or group training, AR allows employees to pursue education and upskilling through augmented feedback, delivered in real-time, in context. Glasses that identify when an action is completed properly, for example.

AR training also expands the capabilities for accessing a knowledge base. Proctors don’t need to stand by to provide insight and employees don’t need to sift through complicated manuals to find information — they can rely on AR technology to quickly find the answers. Social distancing, revolving schedules, and sanitization practices can’t undermine AR.

AR enables the future

The skills gap is still a problem for manufacturing, but that shouldn’t stop manufacturers from working to upskill their existing workforce. Upskilling seasoned workers using AR is emerging as one of the best solutions. As AR becomes better and factories become more accepting of digital training solutions, workers and employers alike are bound to benefit.