Additive Manufacturing’s Surprising Avenue: Food

Additive manufacturing has been one of the biggest buzzwords over the last few years. Usually, the hype is around 3D printing for construction or fabrication, using extruded materials to create solid forms — everything from 3D printed cement houses to extruded metal fabrication. But there’s one avenue for additive manufacturing that doesn’t get a lot of attention. Ironically, it’s this area of additive manufacturing that’s going to grow rapidly in the coming decade. We’re talking, of course, about 3D printed food.

A brief history of 3D printed food

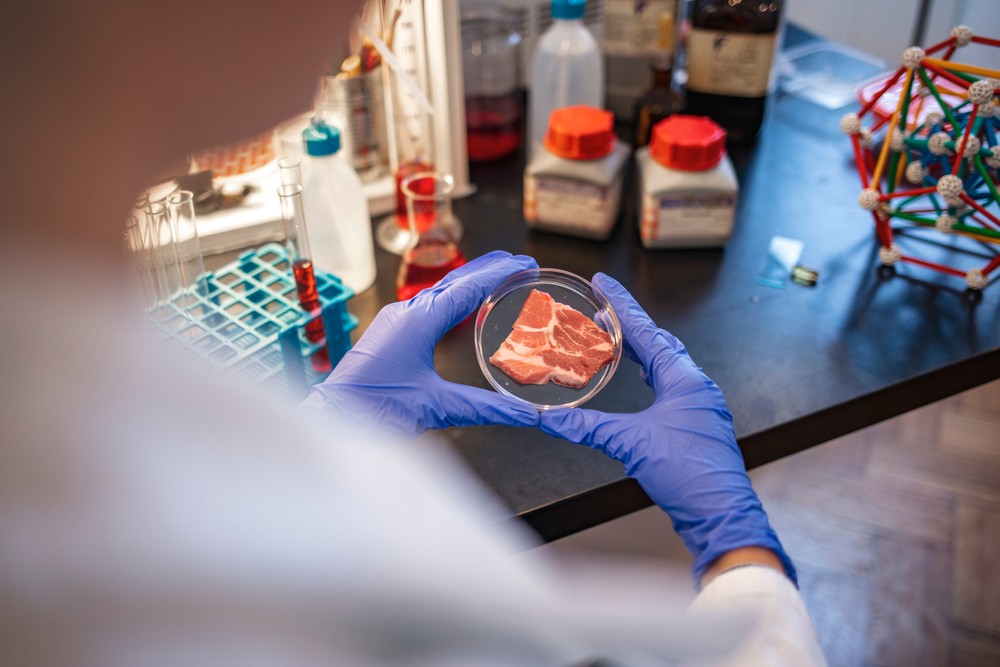

The ability to 3D print food has been around for some time, but not at significant scale. Small extruders are capable of printing paste-like starches and proteins into patties — as is evidenced by the ability to 3D print veggie burgers. Despite this, there’s been little demand or effort to ramp niche extruded foods into full-scale production.

The factors holding 3D printed foods back are few, but significant. First, 3D printed foods have a much shorter shelf life than their traditional counterparts. This is due to protein breakdown, which causes structural breakdown in the printed foods, slowly turning them back into a paste-like gel. Second, lack of nutritional value has been a major concern, as extruded gels lack essential vitamins and macronutrients.

Research into how to alleviate these issues has been ongoing. Now, there appears to be a breakthrough.

Edible ink and 3D printed foods

Researchers at the University of São Paulo’s Luiz de Queiroz College of Agriculture (ESALQ-USP) in Brazil have recently announced successful 3D food printing trials of a hydrogel. The gel, based on modified starch, could be the solution to more stable, nutritional extruded foods in the future. The “ink” is based on a cassava starch, engineered to maintain stable shape and consistency over time, infused with macronutrients.

The researchers used a novel method of extrusion to modify the starch gel to firm up the printing process. In fact, the team was able to control the level of ozone introduced during the extrusion process to produce different print variants, paving the way for more diverse 3D printed foods in the future.

The solution to world hunger?

With the potential for extruded foods at-scale comes an obvious question: is this the solution to world hunger? Unfortunately, it’s too early to tell. 3D printed foods still have a long way to go, and the cost of production will still be significant until there’s widespread adoption of the technologies needed to produce extruded foods.

The good news is that many companies are already poised to bring 3D printed food to the masses at-scale — all they need is the stabilized “ink” to do it. Barcelona-based startup Nova Meat plans to begin selling extruded plant-based products in 2021, as is Israeli startup Redefine Meat. Meanwhile, several companies are poised to bring extruded foods directly into the homes of consumers. Natural Machines and Patisserie Numerique are just two of the companies already producing 3D printing appliances for in-home use, which will benefit from stabilized hydrogels in the future.

While we’re still a long way off from solving world hunger, 3D printed food could be a major stepping stone to understanding broader applications of additive manufacturing across other industries. Success in this sector could very quickly yield success in others as we learn more about how to optimize extrusion and enhance 3D printed products.