AC Motor Maintenance Tasks and Their Recommended Intervals

Industrial AC motors are subject to tremendous wear and tear, so they require significant attention and a thorough, proactive maintenance program, including weekly, monthly, semiannual, and annual preventive procedures.

Dividing AC motor maintenance into specific intervals ensures equipment gets the service it needs to prevent breakdowns, keeps maintenance predictable, and defines standards for its completion. The chief elements of AC motor maintenance, and their recommended intervals, include weekly inspections, monthly preventive maintenance, biannual and annual checks, and addressing issues the moment they arise.

Weekly inspections are key

AC motors experience significant wear and tear in a relatively short amount of time due to continuous operation. Performing weekly inspections prevents this wear and tear from adding up and causing unexpected downtime. General weekly inspections should include:

- Verifying motor cleanliness.

- Checking the fan with a stroboscope.

- Examining the junction box and cables.

- Listening for unusual noise.

- Checking bearing and motor temperatures.

- Inspecting motor casing for visible water.

Catching small problems early will prevent larger ones from developing, and inspections are key to identifying emerging issues. It’s better to prevent a problem than pay for expensive repairs down the line.

Crucial monthly maintenance

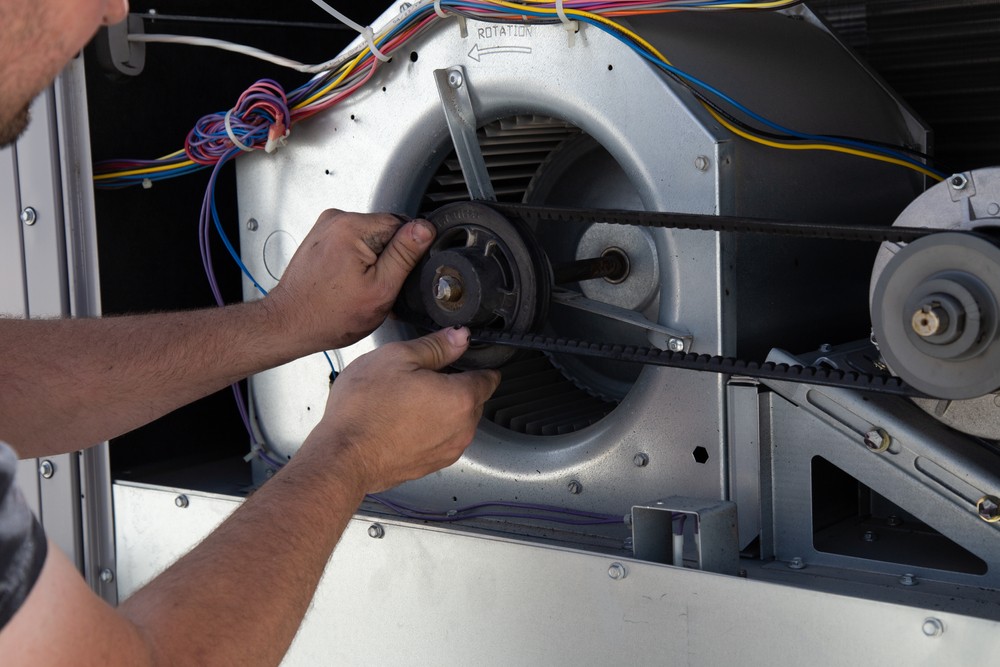

While weekly inspections help prevent small problems, monthly maintenance offers an opportunity to handle emerging issues. Monthly maintenance should include in-depth analysis of a motor’s performance and how it compares to benchmark standards. Monthly AC motor maintenance tasks include:

- Checking and replacing worn brushes.

- Verifying brush pressure and position.

- Checking operating speeds.

- Cleaning windings, commutator, and brushes.

- Examining and tightening loose connections.

- Measuring amperages.

- Removing, cleaning, and replacing oil in sleeve bearings.

- Performing a vibration analysis.

Monthly maintenance goes beyond weekly inspections to address more comprehensive preventive tasks.

Biannual and annual tasks

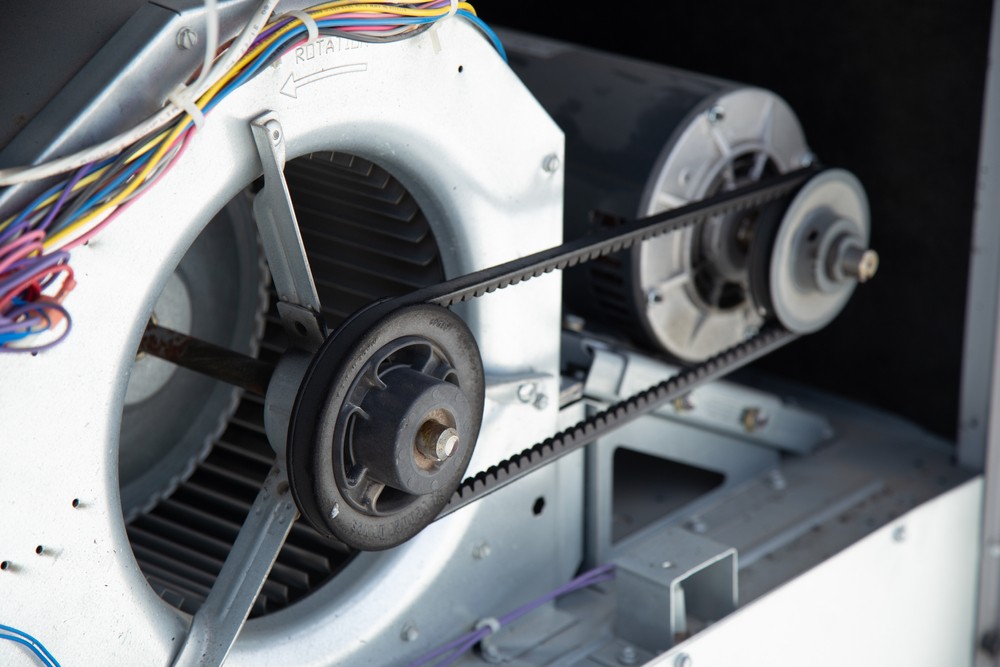

Preventing certain problems requires more invasive procedures that often take more time and effort to address. Barring emerging problems that demand an immediate fix, technicians only perform invasive maintenance tasks once or twice a year. Biannual and annual tasks are critical for the ongoing upkeep of the motor and may include:

- Checking the commutator for slot damage.

- Checking footing and mounts.

- Examining the connections of the commutator and armature coils.

- Performing a full motor function analysis.

- Testing insulation.

Ideally, these biannual and annual tasks are more proactive than reactive. The goal of monthly maintenance tasks and weekly inspections is the prevention of breakdowns and unexpected downtime.

Remedy problems at first sign

Remember, even the best maintenance schedule can’t account for every unforeseen problem. Be as proactive as possible to identify problems, and solve them quickly to keep faults and malfunctions to a minimum. The best way to keep your AC motor running is a comprehensive, regularly scheduled maintenance approach.