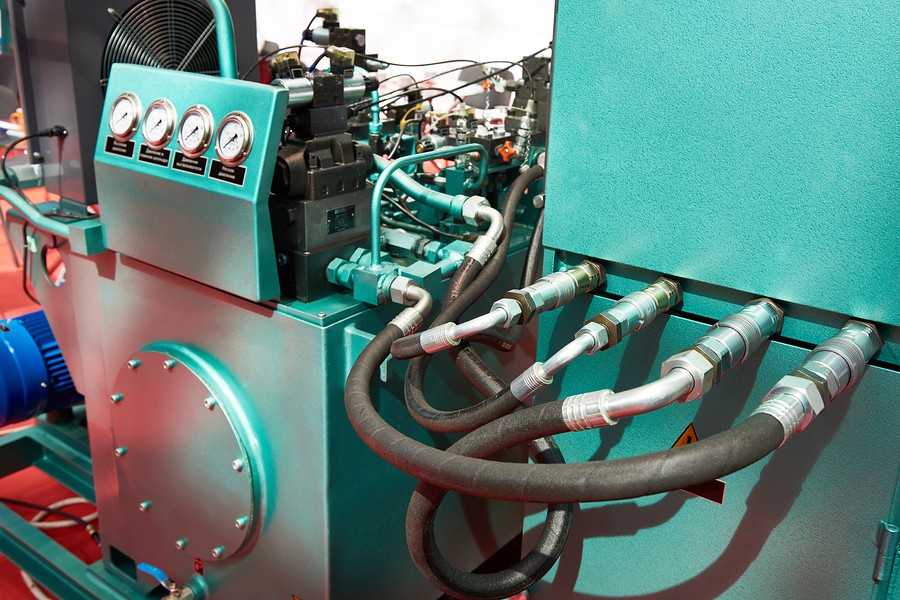

8 Causes of Hydraulic Pump Failure and Why Routine Service Is Important

Hydraulic pumps are at the core of many essential factory operations. Unfortunately, there are numerous pitfalls to plan for, mitigate, and overcome to keep them running. Keeping up on routine maintenance is important, but the best way factory techs can avail themselves of costly, frustrating breakdowns is to understand the various catalysts for hydraulic pump failure.

Causes of hydraulic pump failure

The simplest way to identify the cause of pump failure is to thoroughly inspect and dissect the aftermath of the problem. In most cases, the cause of failure will be evident by the nature of the catalyst(s). Here are eight of the most common problems, some of their defining features, and how they ultimately come to fruition.

1. Fluid contamination is one of the biggest causes of hydraulic pump damage and involves debris mixing with the liquid. This debris causes friction, leading to extenuated wear on the pump itself. The result is inefficiency, culminating in malfunction.

2. Fluid viscosity issues occur when the hydraulic fluid within a pump breaks down over time. Viscosity that’s too high leads to cavitation (another catalyst for damage). Subsequently, if a tech changes and replaces fluid with a viscosity that’s too low, heat and friction become concerns.

3. Over-pressurization occurs because of excessive load on the pump itself, resulting in red-line operation that’s both unsafe and damaging. Hydraulic pumps operating under high duress for extended periods of time will likely experience component wear and premature failure, usually in spectacular fashion.

4. Excess heat can be a product of poor fluid viscosity or environmental factors. This issue is rarely a singular catalyst for pump breakdown, but it exacerbates other factors or masks other issues, such as fluid contamination.

5. Implosion invariably results in extreme failure for hydraulic pumps and is a major safety hazard. Implosion occurs when air bubbles within a hydraulic pump collapse, causing an overload of pressure to the pump that generates an intense shock.

6. Aeration occurs when hydraulic fluid traps air bubbles. The pump subjects the bubbles to pressure, causing high heat and over-pressurization when the bubbles collapse. Aeration at extreme levels leads to implosion.

7. Pump aeration pertains to air not in the hydraulic fluid, but air introduced through unsealed joints or shafts. This air quickly causes pressure instability affecting crucial parts of the pump. This can quickly lead to breakdowns — generally marked by a whine or other high-pitched sound.

8. Cavitation is a symptom of uncontrolled pump speeds, which fail to allow hydraulic fluid to completely fill the pump. It results in destabilized pressure, heat, and excess wear. Cavitation is often marked by the same type of whine or squeal as pump aeration.

Because the factors causing each of these problems differ in nature, it’s best to fully evaluate a damaged hydraulic pump to determine if more than one issue is responsible.

Maintenance equals prevention

Maintenance is the best approach for ensuring safe, efficient hydraulic pump function. But routine service is just the start. Identifying common issues plaguing your hydraulic pumps will lead to a better quality of targeted maintenance — for example, if you pinpoint a heat issue related to viscosity, that issue may be resolved by opting for a different fluid weight.

Every piece of information learned about your pumps can translate into better care, leading to longer uptimes, fewer issues, and fundamentally better maintenance.

Having trouble identifying the catalysts for your hydraulic pump’s issues? Let the professionals at Global Electronic Services take a look! Contact us for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!