Troubleshooting Power Failures: Contextualizing the Problem

Electrical problems are some of the most frustrating to deal with in a factory environment. One moment your equipment is chugging along at an optimal pace, and the next, it’s down and unable to restart. A power failure brings the value stream to a standstill until it’s fixed — which can take time if the cause is difficult to determine. A thorough approach to troubleshooting expedites the process to get equipment up and running again.

Question the equipment at the point of failure

The first step to solving almost any problem is asking the right questions. For best results, start with the most obvious before moving on to the complex. Good questions to ask include:

- Was the device running properly before the failure?

- What was happening at the moment of failure?

- Has this type of problem happened before?

- When did the failure occur?

- Is the issue limited to this piece of equipment?

Asking the right questions helps contextualize the problem. When examining the equipment, have an engineer, regular operator, or maintenance tech standing by for reference. These individuals know the equipment intimately and can quickly identify any oddities or abnormalities present. The goal of questioning is to collect as many details about the failure as possible.

Consult data about equipment function

Since most modern manufacturing equipment is network-enabled, identifying failures is often a matter of checking the digital record of events prior to the failure. IIoT sensors can yield similar insights. Data reveals the equipment’s status right before power loss, and it could identify any events which contributed to it, such as voltage spikes or intermittent power draw.

Data adds context. It won’t tell you exactly why the equipment experienced a power failure, but it can provide the next best thing: insight about the variables leading to the event. Coupled with the context learned from asking questions, relevant data about equipment function can provide the information necessary to fix the equipment and better prepare for future failures.

Perform simple tests

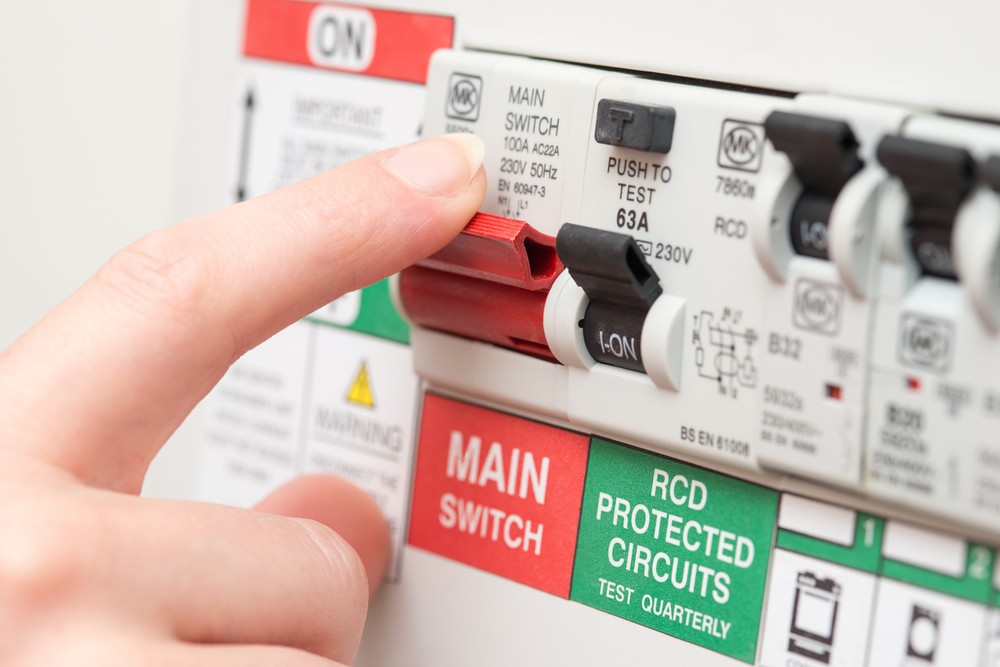

Sometimes, a few simple tests can provide all the information a manufacturing tech needs to execute repairs with confidence. Making sure the equipment can receive the requisite power from its circuit is one example of a simple diagnostic that may save considerable time. Something as simple as a short or a faulty capacitor can bring the entire machine to a halt. Try these simple methods of troubleshooting before moving on to more complex procedures.

There are a variety of testing devices for determining the causes of equipment failure, including voltmeters, current detectors, temperature sensors, and more. Using these devices, repair technicians can identify obvious faults and explore simple solutions to power failure.

Troubleshoot fast and safely

When tackling equipment power failure issues, always make sure the first step is a safe one. Practice lockout-tagout (LOTO) on all power sources and ensure machinery is truly locked and safe before performing any tests. Just because it’s not working doesn’t mean it’s safe to assess! A safe approach is imperative — and it makes for quicker troubleshooting.