Speeding Up Production Time with Additive Manufacturing

Production times are often what set manufacturers back from being able to take on new customers and orders. Consider what it would be like to speed up production time considerably — and accept new projects to boost your bottom line. With speedy additive manufacturing, it’s possible. This technology has already been disrupting in the industry — and could be exactly what you need to enhance your own operations. But how is it progressing as a manufacturing tool?

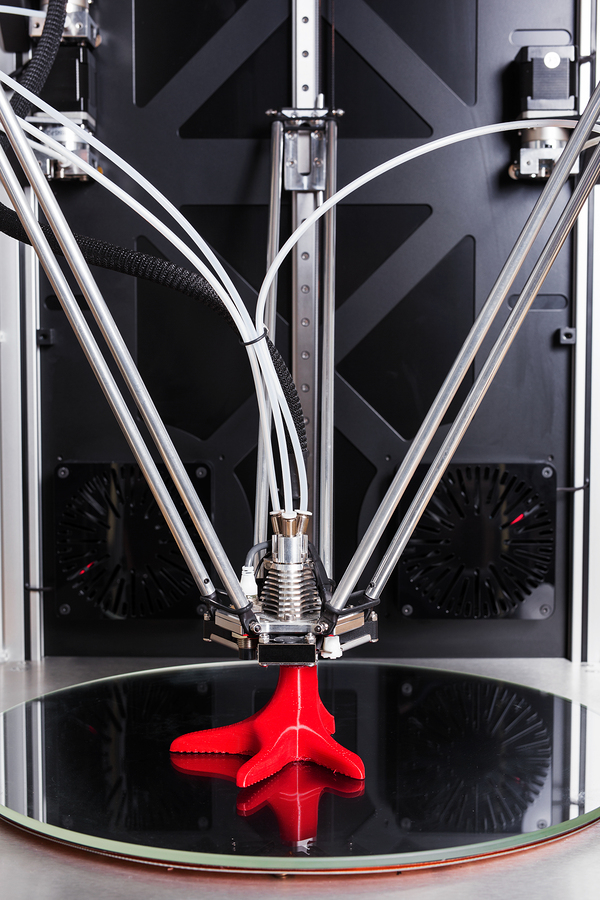

While additive manufacturing using polymers has long held the spotlight, the technology now encompasses the ability to print using concrete, ceramics, and metal among other materials. In addition, it’s grown to allow for production in space. But the number of printable materials and their applications aren’t the only 3-D printing aspects that are changing. Once upon a time, it took manufacturers hours or even days to create new models. Now, with faster and more accurate 3-D printing, it can take just minutes to have a fresh model in front of you.

Just how fast is additive manufacturing?

Some new 3-D printers can produce at speeds 10 times faster than their previous counterparts. While smaller commercial printers can print at the rate of approximately 20 cubic centimeters per hour, it’s now possible for manufacturers to print new designs, replacements for broken parts, and more in just minutes — or even faster.

In terms of 3-D printing speed, manufacturers consider three main factors:

- The speed of the print head

- How fast the print head can melt the printing material

- The amount of force pushing the printing material out

Behind manufacturers’ demand for this speed is the ability to make repair parts or build new products faster. By increasing all three factors, they can speed up these production processes. However, actual production speed isn’t the only aspect additive manufacturing is good for. It is also capable of speeding up manufacturers’ ability to produce prototypes more quickly. This helps them create, test, and send new models to production faster. It also enhances customer service as they can speed up delivery times, allowing them to beat their competition and gain new customers. In addition, increasing 3-D printing speed allows manufacturers to perform equipment repairs faster as they’re able to manufacture replacement parts on the spot as opposed to ordering and waiting for new parts to arrive via lengthy processing and shipping times.

Behind manufacturers’ demand for this speed is the ability to make repair parts or build new products faster. By increasing all three factors, they can speed up these production processes. However, actual production speed isn’t the only aspect additive manufacturing is good for. It is also capable of speeding up manufacturers’ ability to produce prototypes more quickly. This helps them create, test, and send new models to production faster. It also enhances customer service as they can speed up delivery times, allowing them to beat their competition and gain new customers. In addition, increasing 3-D printing speed allows manufacturers to perform equipment repairs faster as they’re able to manufacture replacement parts on the spot as opposed to ordering and waiting for new parts to arrive via lengthy processing and shipping times.

The advent of speed is bringing a significant amount of future potential to additive manufacturing. According to Gartner, 3-D printing could result in over 6.5 million printer sales by 2020. It could reduce product timelines in terms of design, prototyping, actual product development, and final production. It will also likely enhance production flexibility. Another 3-D printing benefit is it could allow manufacturers to create uniquely customized products as well as special limited series quickly without having to worry about expensive and lengthy processes.

With so many intertwined cost and speed benefits, will you make an investment in 3-D printing for your facility? Understanding all benefits of using new additive manufacturing technology could help you decide whether it’s time to make the leap.

At Global Electronic Services, we’re here to help you with your manufacturing repair needs. We specialize in industrial electronics, AC and DC motor, hydraulic and pneumatic, as well as servo motor repairs. Learn more about speeding up repair times for your manufacturing facility by contacting us today!