Starter Terminal Lugs

It’s usually not a good idea to leave electronic devices or appliances running all the time. They would sustain excessive wear and tear, burn out their motors or cause fires or injuries if left unattended.

An electrical device needs a starter to create an electrical connection when the user turns it on. This is where starter terminal lugs come in. These components provide sturdy, stable housings that allow for the creation of electrical currents to start a device.

-

OMRON

OMRONOmron Keylock Switches A22TK-2LL-12-K02 Repair Service and Sales

- Model #:

- A22TK-2LL-12-K02

- Part #:

- A22TK-2LL-12-K02

- New/Surplus $ 176

- Refurb. Price $123 Save up to $ 53

- Repair Price $88 Save up to $ 88

-

Allen-Bradley

Allen-Bradley599-TW4: Allen-Bradley Top Wiring Kit

- Model #:

- 599-TW4

- UPC #:

- 66207211619

- Part #:

- 599-TW4

- New/Surplus $ 243

- Refurb. Price $170 Save up to $ 73

- Repair Price $122 Save up to $ 121

-

Allen-Bradley

Allen-Bradley599-TW01: Allen-Bradley Top Wiring Kit

- Model #:

- 599-TW01

- UPC #:

- 78118015678

- Part #:

- 599-TW01

- New/Surplus $ 33

- Refurb. Price $23 Save up to $ 10

- Repair Price $17 Save up to $ 16

-

Allen-Bradley

Allen-Bradley199-LJ1: Allen-Bradley Terminal Lugs

- Model #:

- 199-LJ1

- UPC #:

- 66207216080

- Part #:

- 199-LJ1

- New/Surplus $ 385

- Refurb. Price $270 Save up to $ 115

- Repair Price $193 Save up to $ 192

-

Allen-Bradley

Allen-Bradley150-SCBK: Allen-Bradley SMC-50 Frame C External Bypass Kit

- Model #:

- 150-SCBK

- UPC #:

- 88673997255

- Part #:

- 150-SCBK

- New/Surplus $ 739

- Refurb. Price $517 Save up to $ 222

- Repair Price $370 Save up to $ 369

-

Allen-Bradley

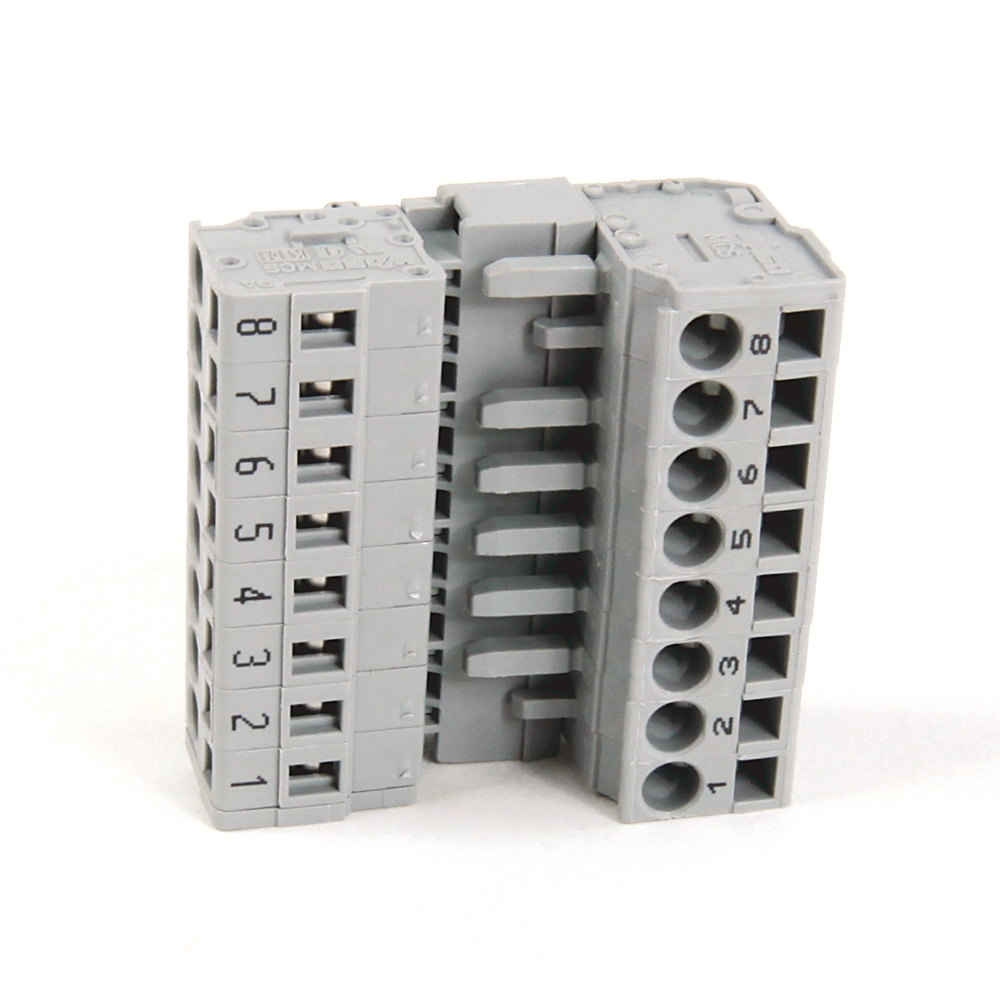

Allen-Bradley141A-APC8: Allen-Bradley MCS Mounting System Control Plug

- Model #:

- 141A-APC8

- UPC #:

- 61132077872

- Part #:

- 141A-APC8

- New/Surplus $ 53

- Refurb. Price $37 Save up to $ 16

- Repair Price $27 Save up to $ 26

What Are Starter Terminal Lugs?

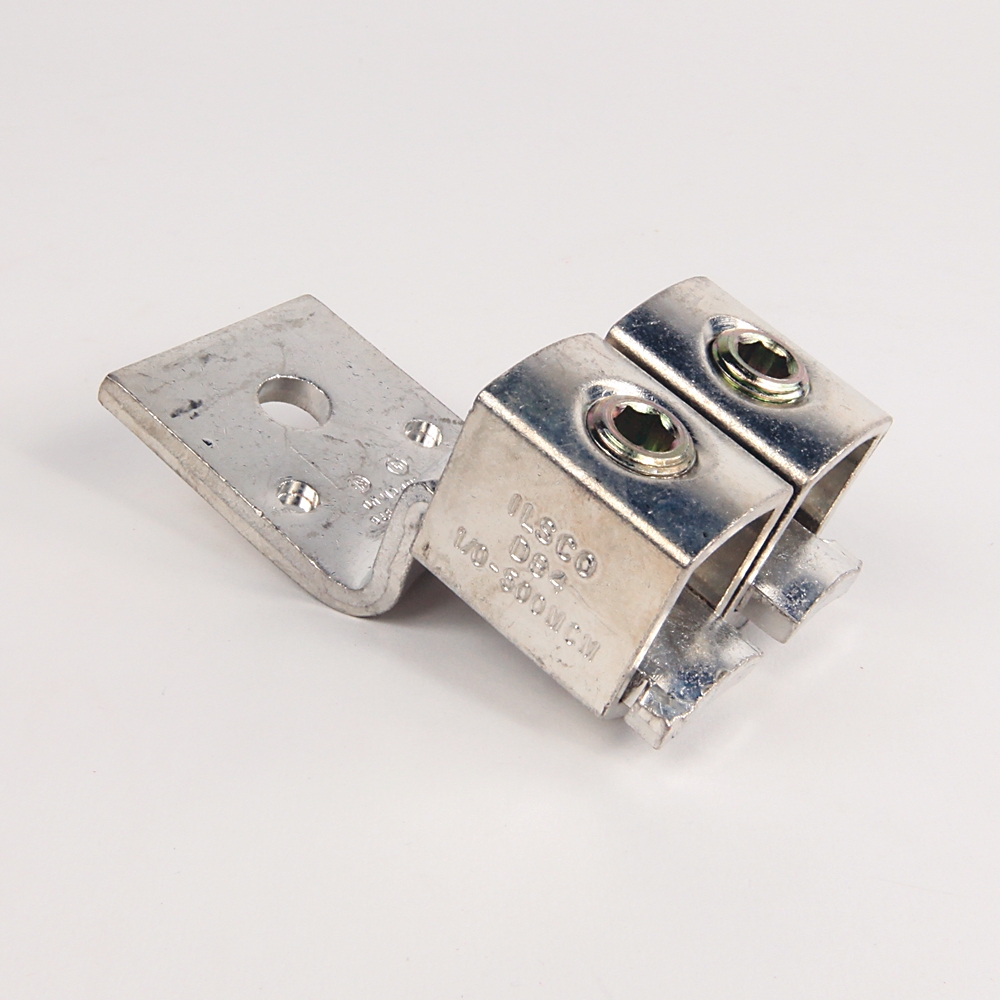

What are starter terminal lugs? They are devices that attach to a conductor to form a connection with the terminal, usually by attaching the wires to the terminal studs. With stranded wires, they also hold the wire’s strands together.

Starter terminal lugs are often straight components consisting of a barrel, wire and tongue, with some lugs containing different types of insulation and insulation support as well. They may also take the form of right-angle lugs — in which the barrel forms an angle with the tongue — or wider flag-shaped lugs.

The terminal’s design facilitates mounting it to another object like a chassis, stud or post. The terminal has specific features optimized for the attachment of electrical conductors — the wires — that enable the formation of an electrical connection. Attaching the wires usually requires particular tools.

A starter terminal lug often contains several different components:

- – Barrel

- – Tongue containing an open eyelet

- – Stripped wire

- – Wire insulation (optional)

- – Color-coded insulation (optional)

- – Insulation support (optional)

The tongue’s eyelet is a circular opening designed for mounting. Some terminal lugs have one eyelet, and some have two. The eyelet may take numerous forms, including block spade, flanged spade, ring spade, hook or ring. The metal near the eyelet also often contains the manufacturer’s mark.

A couple different parameters determine the composition of the starter terminal lug. These are typically the size of the wire that will fit the barrel and the tongue width that will accommodate a specific stud. The barrel may also be insulated or noninsulated.

The complete assembly of the starter terminal lug will include a bolt, nut, washer and spring lock washer. These components hold parts of the starter terminal lug securely in place and enable it to function effectively.

Starter and Contactor Terminal Lugs

What are contactor terminal lugs? Contactor terminal lugs are essentially the same as starter terminal lugs.

In electronics, a contactor is an electrically controlled device that turns the power on and off in a circuit. A contactor is similar to a relay, which also connects two points in response to a control signal.

A starter is a contactor with an additional protective device known as an overload relay. An overload relay is a device that protects the motor by controlling the circuit’s current. It keeps the motor from becoming overloaded and sustaining damage from excessive heat.

Either scenario requires a terminal lug to facilitate the electrical connection. A starter or contactor terminal lug makes it possible for a piece of equipment like a motor to operate.

Uses for Starter Terminal Lugs

What are some uses for starter terminal lugs? These lugs are common components in any application that requires starting a motor. They are useful in many electrical devices, appliances, lawn and garden implements and various types of medical equipment.

Common Questions and Problems for Starter Terminal Lugs

Starter terminal lugs aren’t always intuitive to use at first. Below are a few frequently asked questions, as well as a few issues that may arise.

What Are Some Different Techniques for Attaching the Starter Terminal Lug?

A few different methods are useful for attaching the terminal to the conductive wire:

- – Crimp-on method

- – Press-on method

- – Screw-on method

- – Soldering

What Are the Advantages of Solderless Terminal Lugs?

Solderless terminal lugs offer a few advantages over their soldered counterparts. They are generally easy to use, unlike soldered terminals, which tend to require advanced operator skills.

Crimp-on terminals also require only one tool, the plier-like crimp-on device, instead of multiple implements. Using only a single tool makes the application process much quicker and easier to perform. The technician can make connections rapidly, and they will be clean and uniform.

How Should Your Company Choose the Right Starter Terminal Lug for the Wiring?

The starter terminal lug material must match the material in the wiring. Copper wiring will require copper terminals, for instance, and aluminum wiring will require aluminum terminals. The terminal and stud hole sizing should also be a good match for the wire sizing, and the cross-sectional area of the wires should not be bigger than the cross-sectional area inside the lug.

How Many Wires Can Go Into a Starter Terminal Lug?

In general, three wires is the maximum number of wires that can terminate in a starter terminal lug. A greater number of wires presents a safety hazard. Sometimes a lug has multiple parts — for instance, it may be bifurcated, have multiple holes or contain a multi-section turret. In these cases, the number of wires in each section should not exceed three.

Issues With Starter Terminal Lugs

Below are a few issues that can occur with starter terminal lugs:

- – Soldering imperfections: Using a starter terminal lug often involves soldering it to the terminal stud. Soldered terminals have their limitations — an improperly soldered terminal will be defective, so a highly skilled technician is indispensable.

- – Faulty connections: Beyond improper soldering, various factors can lead to connection defects, including flux, temperature, oxides, cleanliness and insulation damage from heat. Addressing these issues is essential for optimal starter terminal lug performance.

- – Terminal lug replacement: A lug is of no use to your business if it has become worn down and can’t do its job effectively. At some point, your company may need to replace a starter terminal lug. Check for signs of wear or corrosion so your organization can make timely replacements.

Benefits of Working With Global Electronic Services for Starter Terminal Lugs

Working with Global Electronic Services gives your business the peace of mind of knowing you’ll get quality equipment that can stand up to heavy use and tough jobs. We have a full range of starter terminal lugs available for purchase. We are also certified to service a wide variety of brands, so no matter who made your equipment, we’ll likely be able to fix it if it needs repairs.

Make Global Electronic Services Your Trusted Source for Starter Terminal Lugs or Starter Terminal Lug Repair

To gain quality starter terminal lugs, work with Global Electronic Services. Browse our offerings on this page to find the models that will work best for your electrical needs.

Contact us today to purchase starter terminal lugs, schedule equipment repair or learn more about what we can do for your company.