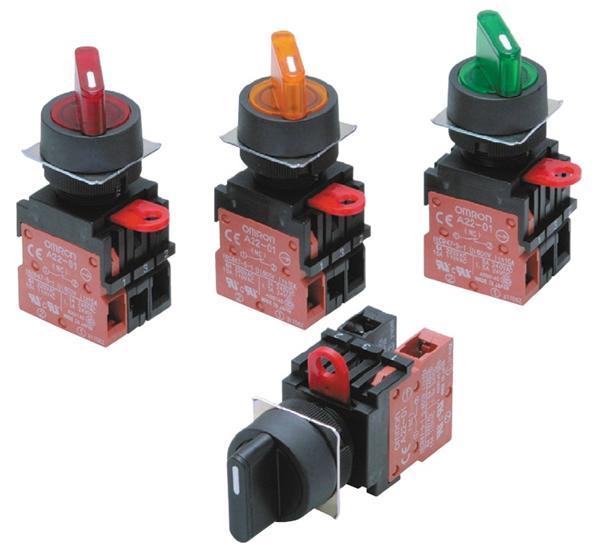

Manual Starters

Manual motor starters are simple devices that can protect equipment from various threats and offer convenient on/off switches. They’re often used with smaller motors to keep these components running safely and smoothly for fewer issues, less downtime, and less risk of damage to the equipment.

Browse our manual starters below.

-

OMRON

OMRONOmron Switch Hardware A22NZ-A-C01 Repair Service and Sales

- Model #:

- A22NZ-A-C01

- Part #:

- A22NZ-A-C01

-

OMRON

OMRONOmron Switch Hardware A22NZ-H-01 Repair Service and Sales

- Model #:

- A22NZ-H-01

- Part #:

- A22NZ-H-01

-

OMRON

OMRONOmron Switch Hardware A22NZ-A-50103 Repair Service and Sales

- Model #:

- A22NZ-A-50103

- Part #:

- A22NZ-A-50103

-

OMRON

OMRONOmron Keylock Switches A22NZ-3RM-01AA Repair Service and Sales

- Model #:

- A22NZ-3RM-01AA

- Part #:

- A22NZ-3RM-01AA

-

OMRON

OMRONOmron Rotary Switches A22S-C3M-11 Repair Service and Sales

- Model #:

- A22S-C3M-11

- Part #:

- A22S-C3M-11

-

OMRON

OMRONOmron Keylock Switches A22TK-2LL-11-01 Repair Service and Sales

- Model #:

- A22TK-2LL-11-01

- Part #:

- A22TK-2LL-11-01

- New/Surplus $ 145

- Refurb. Price $102 Save up to $ 43

- Repair Price $73 Save up to $ 72

What Is a Manual Motor Starter?

Manual motor starters are an electromechanical device that protects a main circuit from short-circuiting, phase loss, and overloads. These devices can also be called motor protection circuit breakers (MPCBs) or manual motor protectors (MMPs) and their protection is fuseless. Their primary use is to switch motors on and off with this added protection.

How Does a Manual Motor Starter Work?

Typically, a manual motor starter is triggered by a button or toggle. Once flipped or pressed, the contacts open up and the motor starts working. The motor’s capacitor and coils control direction for single-phase induction motors.

The manual motor starter protects from short-circuits by disconnecting the motor if the current exceeds safe values, and it protects from overloading via overload relays built into the device. These protections ensure the right amount of current reaches the motor and control temperatures for better efficiency and safety.

What Are the Benefits of a Manual Motor Starter?

Manual motor starters offer a type of fuseless protection, which can deliver savings on costs while enabling a quick, millisecond-level reaction when necessary. Other benefits to a manual motor starter include:

- A space-saving design.

- Reduced downtime and machine damage from electricity issues.

- Several functions in one component.

- Worldwide approvals.

If you need quick protection for smaller motors, a manual motor starter might be a good choice.

Applications for Manual Motor Starters

One important factor to note about manual motor starters is that they don’t always disengage the motor’s power if the supply is interrupted. So, if the power goes out in a facility, anything powered by a manual motor starter would spring back on when the power gets restored.

This applies unless the starter has under-voltage protection. With this type of technology in place, the starter circuit is de-energized after an interruption.

These features are significant when deciding where to place a manual motor starter. For instance, if it doesn’t have under-voltage protection, you wouldn’t want to hook it up to equipment that would be dangerous to spontaneously restart, such as conveyor belts or machining tools. A better machine choice would be something that runs continuously and has a smaller motor.

However a manual motor starter is used, you’ll want to ensure it matches specifications for phase numbers, voltage, currents and power ratings.

Repairing or Replacing Manual Motor Starters

Even the best manual starters are subject to damage or technical problems. If you think you may need to replace or repair a manual motor starter, Global Electronic Services can help. We have a wide inventory of manual starters and can conduct quick, affordable repairs with the help of our skilled technicians. Browse our product selection to learn more, or reach out to us for a quote!