Manufacturing in the Fight Against COVID-19

Just a couple of months ago, headlines tolled a death knell for domestic manufacturing. Recession was just on the horizon, with a dim outlook beyond. Now, as if triggered by a starter’s pistol, manufacturing is off and running again. The problem is, the industry isn’t prepared for such an upswing. COVID-19 is pushing industry hard and fast, and the stakes are high. Many manufacturers are kicking it into overdrive to help, with more joining by the day. The question is, will they catch up to demand before COVID-19 snuffs out the same manufacturing renaissance it started?

Manufacturers are answering the call

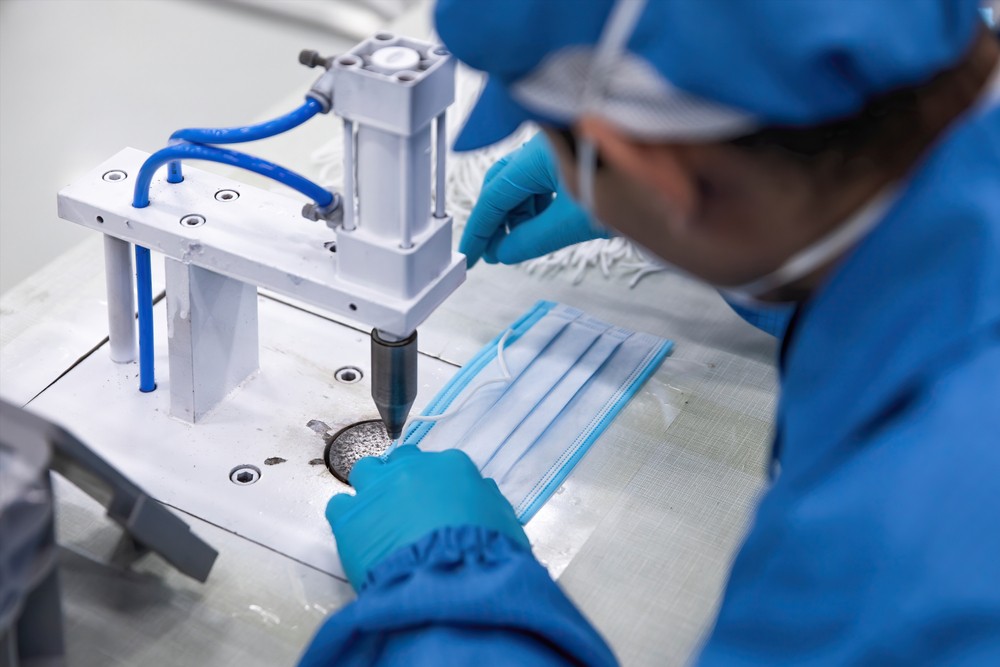

Manufacturers from every sector must answer the call for help against the spread of COVID-19. Pharmaceutical and medical manufacturers are on the front lines, producing everything from drugs to durable medical equipment like ventilators used in treatment. Food manufacturers are close behind as consumer demand skyrockets over fear of quarantines and lockdowns. Textile manufacturers and producers of personal protective equipment (PPE) are stretched thin as they ramp up production of vital necessities.

Manufacturers with no direct production capabilities are finding ways to help as well. Electronics manufacturers are lending technologies to other producers. Automakers like GM are leveraging partnerships to funnel funds and manpower into production of life-saving equipment like ventilators. Even the ever-noteworthy CEO Elon Musk has chimed in to offer help.

The race against time

While it’s amazing to see the agility and flexibility of so many manufacturers across the spectrum of industry, there’s a looming problem hampering their efforts — time.

Based on projected models generated by examining the spread of COVID-19 in China and Italy, the U.S. is experiencing new cases at an unprecedented rate. In a stratagem to flatten the curve, the U.S. is quickly running up against a wall. Hospital infrastructures could become even more overwhelmed. PPE like essential n95 masks will run out, causing the virus to spread quicker in hospitals. Ventilators won’t accommodate the rise in severe cases reported, leading to a higher mortality rate. The list goes on.

Manufacturers are up against the clock. Who can move faster: production lines or the virus?

What does manufacturing need to do?

As manufacturing races to support the fight against the COVID-19 pandemic, the industry as a whole needs to hunker down. Manufacturing’s success will stem from its ability to achieve specific goals:

- Keep transmission rates in factories low, so the workforce remains healthy.

- Maintain peak production levels of essential items like PPE, food, and medical supplies.

- Repurpose non-critical supplies to mission-critical operations.

- Continue to keep people employed and operations running.

Industry bellwethers are cognizant of these goals and working hard to engrain them in their operations. There have been cross-border efforts to aid countries hit hard by the virus, whose manufacturing efforts are stunted. The longer domestic factories can keep their production lines running, the better able we are to fight back against COVID-19.