Lean Manufacturing

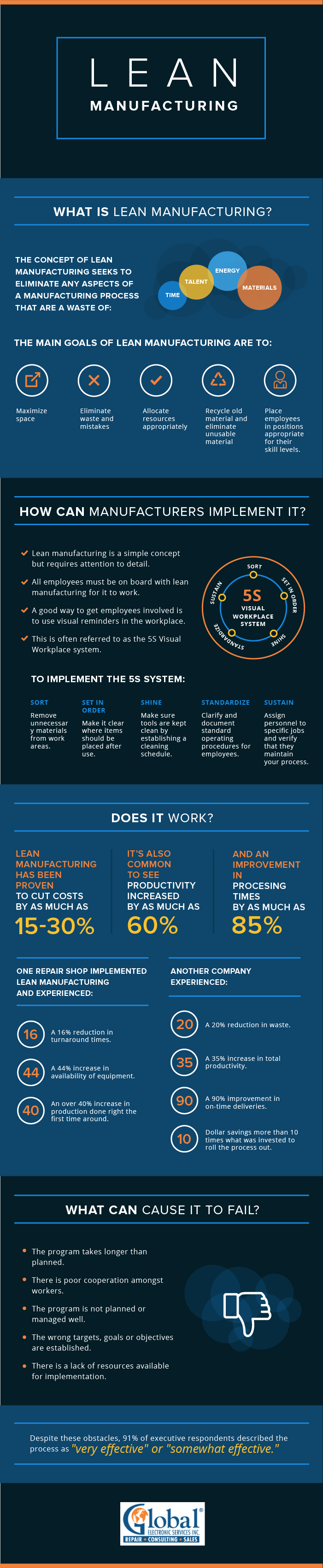

Lean manufacturing is an industry buzzword that many people have heard but not many understand. The core of lean manufacturing is to eliminate any waste in the manufacturing process. That includes wastes of time, talent and energy in addition to the waste of materials. Let’s take a closer look at lean manufacturing and how manufacturers and team leaders can implement this process in their own facilities.

The Main Goals of Lean Manufacturing

What are the goals of lean manufacturing in this industry?

The primary goal of lean manufacturing is to maximize usable space within the facility, eliminate all waste, prevent mistakes and properly allocate resources. Lean manufacturing facilities also strive to recycle all old materials and to eliminate unrecyclable or unusable materials from their processes, as well as place employees in positions that are appropriate for their skill levels.

Efficiency on every level is the core of lean manufacturing. It sounds simple, but it isn’t always as easy as it sounds.

Implementing Lean Manufacturing

How can manufacturers implement lean manufacturing practices in their own facilities? This is a simple concept but it requires both intense attention to detail and complete cooperation from all workers, regardless of their position.

One way to get employees involved is to provide visual reminders and utilize the “5S” system. The 5S system is based on five Japanese words: Seiri, Seiton, Seiso, Seiketsu and Shitsuke. Loosely translated into English, this breaks down to:

- Sort: The Japanese word “seiri” translates to “tidiness.” The key to this step is to remove any unnecessary materials from the workplace.

- Set in Order: “Seiton” means “orderliness.” Keep all of your materials carefully organized throughout the manufacturing process.

- Shine: “Seiso” translates to “cleanliness.” This step requires a routine cleaning of all work areas to ensure tools and equipment are kept clean and functional.

- Standardize: This is a straight translation. “Seiketsu” means “standardization,” and this step requires that operating procedures are both clear and consistent for all employees.

- Sustain: “Shitsuke” translates to “discipline” and refers to the ongoing effort, by all employees, that it will take to sustain a lean manufacturing environment.

Does It Work?

Does lean manufacturing work? The numbers actually tend to speak for themselves. This style of manufacturing has been proven to cut costs by as much as 30 percent and increase productivity by as much as 60 percent. Processing time also sees a dramatic improvement of up to 85 percent.

A repair shop that implemented lean manufacturing practices experienced a 16 percent reduction in their turnaround times as well as a 44 percent increase in equipment availability and a 40 percent rise in correct job completion the first time.

Another company experienced a 20 percent reduction in manufacturing waste, a 35 percent productivity increase and a 90 percent improvement in on-time deliveries. They ended up saving more than 10 times what they put into the initial lean manufacturing rollout.

Lean Manufacturing Failure

What causes lean manufacturing to fail?

Programs that aren’t planned and managed well, or ones that take too long to implement, can often end in failure. Programs that are implemented without the full cooperation of all employees are also doomed to failure. If the company doesn’t have enough resources to fully implement lean manufacturing practices, it can also lead to failure, as this can cause leaders to set the wrong goals at the beginning.

In spite of these possible causes of failure, most people believe in lean manufacturing. Some 91 percent of manufacturing representatives, when surveyed, stated that they felt lean manufacturing was either “every effective” or “somewhat effective” in improving productivity, reducing waste and increasing efficiency.

Lean manufacturing is one of those practices that takes a few minutes to learn but a lifetime to master. It requires constant cooperation from all employees on every level, from trainees to management, and must be constantly maintained. It can be hard work, but the benefits are nearly limitless.