How to Practice Industrial Recycling Stewardship

With each passing year, manufacturers become more aware of their contributions to downstream waste. Faced with an environmental crisis on one side and overwhelming demand for mass-produced products on the other, manufacturers are in a precarious spot. Nevertheless, there’s an opportunity for producers to become stewards — exemplars who can play an important role in shifting our linear economy toward a more circular, sustainable one. It starts with a focus on recycling.

What does it mean to be a recycling steward?

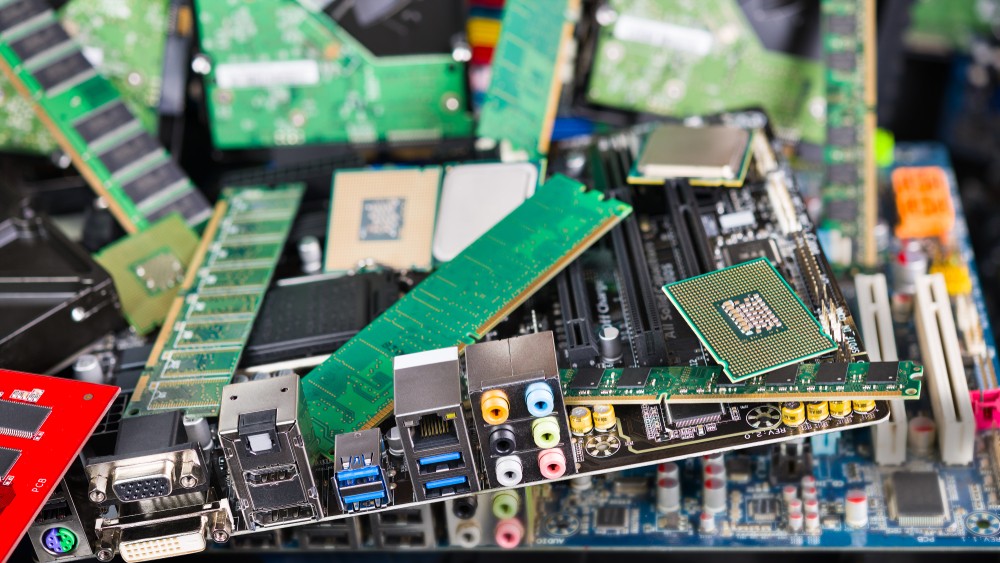

With the threat of climate change growing ever greater, it’s up to everyone — whether you work in the manufacturing industry or not — to responsibly recycle electronics, or e-waste. Manufacturers and other goods producers are in the unique position to affect change through recycling at two levels: initial production and material re-use.

From reusing electronics components to properly recycling unnecessary components, there are several ways to do your part for the environment by handling electronics responsibly. A long-term, mindful approach to recycling stewardship is critical. Those who take action and an effortful approach to recycling e-waste set the tone as stewards.

Why should we recycle e-waste?

Electronics contain a myriad of valuable, depletable raw materials like copper, gold, iron, oil, palladium, platinum, and more. Recycling electronics not only allows manufacturers to reclaim these materials, but also reduce the total amount of debris present in waste disposal sites around the world. More material recycled means less mined from the earth, which is a core pillar of a circular economy.

The major benefits of recycling e-waste

Sustainable electronics management provides a wide range of benefits, not only for manufacturers but for society in general. For example, recycling e-waste creates more green jobs that support a vibrant recycling and refurbishing industry. Other key benefits of recycling e-waste include:

- Environmental. Like anything else in a landfill, electronics take up space. Recycling electronics waste rather than throwing it away keeps unnecessary items out of the landfill, while reducing environmental pollution caused by toxins that leech into the ecosystem.

- Economic. Manufacturers who use recycled materials in production create less pollution, all while using less water and energy to make goods. Also, by recycling components rather than making them from scratch, manufacturers can lower the overall production costs of goods.

- Efficient. Recycling e-waste allows manufacturers to reuse resources. Electronics often contain several components that producers can reutilize, often without any further processing. This conserves resources and energy required for initial manufacturing.

Building a circular economy

What are you doing to tackle the problem of e-waste, and waste in general? It’s every manufacturer’s job to be mindful of what goes in the scrap heap and to make a concerted effort to reclaim as much as possible.

Managing e-waste appropriately can save valuable resources, reduce pollution, and conserve energy — and it’s often in the best interest of manufacturers to accept e-waste or work with a partner that specializes in reclaiming crucial materials.

Recycling needs to happen at a grand scale around the world, and as a recycling steward, manufacturers have the power to lead the way.