Five Flowmeter Types

Flowmeters are helpful devices used in a variety of industries to measure the flow rate of a fluid as it passes through a pipe. These fluids could be water, oil, natural gas, steam or anything else. While all flowmeters share a common function, they are a bit different in the way they operate.

We’re going to discuss some considerations for choosing the best flowmeter for your work, then look at five common types of flowmeters and their applications. Then, we’ll talk about what to do if your company experiences a problem with a flowmeter.

Considerations to Make When Choosing a Flowmeter

When you’re looking for a flowmeter, you need to consider some crucial factors to make the best choice for your company’s application. If there were one flowmeter that worked perfectly for every situation, there wouldn’t be countless other flowmeter types to choose from. The reality is that there are many types of flowmeters, and their uses vary. Each flowmeter offers various advantages and capabilities that make it a valuable option in certain instances.

1. Fluid Properties

To start, you want to consider the properties of the fluid you’ll be measuring. First, is the fluid a liquid, a gas or steam? How dense or viscous is it? Does it contain any contaminants, such as air bubbles or debris, that could affect the reading?

One critical aspect of the fluid to consider is its Reynolds number. This value tells you about how a fluid moves through a pipe. If the number is under 2,000, the flow is laminar, meaning it flows steadily. If the number is higher than 2,000, the fluid is more turbulent. As you look at flowmeters, pay attention to the Reynolds range they are designed to handle, so you can ensure they’re a good fit for your application.

You may need to ask yourself some different questions about your fluid’s properties, depending on which types of flowmeters you’re considering. For example, if you want to use an electromagnetic velocity flowmeter, you’ll need to determine whether your fluid is a conducting substance.

2. Accuracy

Once you know the variables of the fluid you plan to measure, you can begin to look for a flowmeter designed to deliver an accurate reading for your application.

In many cases, you’ll have multiple options to choose from, all of which can work with your situation. However, some may offer a higher degree of accuracy than others. Pay attention to the level of accuracy different flowmeters can deliver. Generally, one of the most accurate types of flowmeters you can find is a positive displacement flowmeter, but this may not always be the best choice, depending on what you are using it for.

We typically see accuracy measured in terms of a percentage, such as ±1%. In this example, the reading on the flowmeter could be as much as 1% above or below the actual value. Therefore, the lower the percentage, the more accurate the flowmeter is.

3. Cost-Effectiveness

Cost is a practical concern that is always worth noting. You may find a flowmeter that would deliver highly accurate results, but is outside the confines of your budget. Try to balance finding the best possible option with affordability.

Remember, cost-effectiveness isn’t only about the price tag. You might find an exceptionally cheap option that seems like it will work. However, if it’s too inaccurate or stops working shortly after you install it, it will end up costing you more in the long run, since you’ll have to replace it.

Look for an option that offers quality and durability, even if that means spending more than you’d like to upfront. This strategy enables you to get the most out of your flowmeter over time.

Types of Flowmeters

There are many types of flowmeters. Each type goes about measuring the flow rate of a fluid in a different way. We’re going to look at five main types of flowmeters you can find on the market today, including differential pressure flowmeters, velocity flowmeters, positive displacement flowmeters, mass flowmeters and open-channel flowmeters.

1. Differential Pressure Flowmeters

One of the most common types of flowmeters is called a differential pressure (DP) flowmeter. This flowmeter type is based on scientific principles that govern the way fluids, both liquids and gases, flow through pipes.

To maintain a consistent flow rate, a fluid that moves from a wider pipe to a narrower one will have to move through with a greater velocity. When a fluid’s velocity increases, the pressure decreases. What does a change in pressure have to do with flow rate?

According to Bernoulli’s theorem, you can accurately calculate a fluid’s flow rate based on the square root of the differential pressure. In other words, if you can determine the differential pressure, you can determine the flow rate. There are different types of DP flowmeters, but all of them operate according to this principle.

In a differential pressure flowmeter, the fluid you are measuring enters a narrower section of pipe, sometimes by way of an orifice plate. As the name suggests, a differential pressure flowmeter measures the difference in pressure that occurs as a result of the flow-restricted area. Then, a DP flowmeter does the necessary math to display the fluid’s flow rate.

Differential flowmeters are common throughout many industries that need to measure the flow rate of fluids. These include the oil and gas, water treatment, pharmaceutical, food and beverage, mining, chemical manufacturing and HVAC industries, among others.

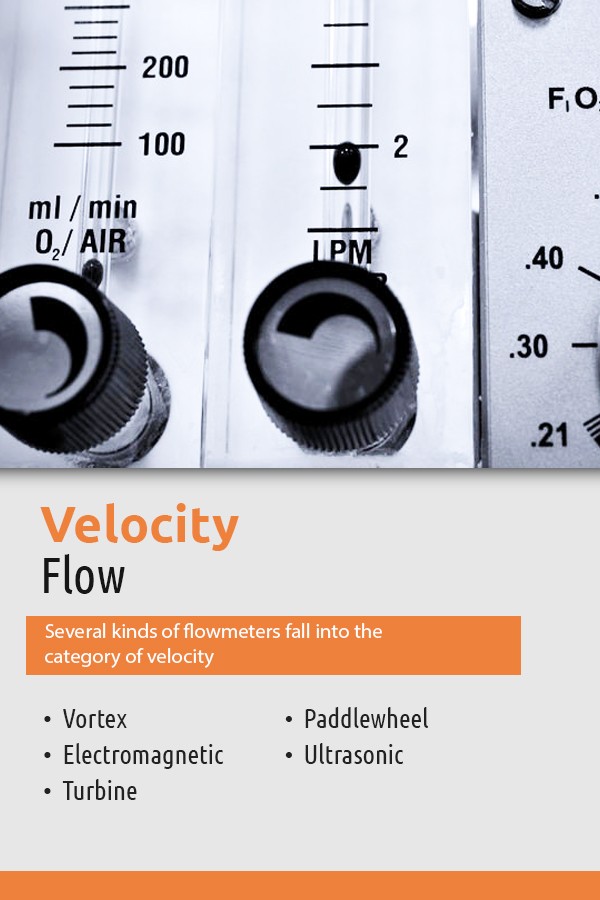

2. Velocity Flow

In the case of velocity flowmeters, the flowmeter working principle is that the flow rate of a fluid is equal to a cross-section of the pipe multiplied by the fluid’s velocity. By measuring the velocity of the fluid flowing through the pipe, then, a velocity flowmeter can determine the fluid’s flow rate. Several kinds of flowmeters fall into the category of velocity flow.

- Vortex: Vortex meters include an obstruction that disrupts the fluid’s flow and causes it to form vortexes. The number of vortexes formed indicates the fluid’s velocity.

- Electromagnetic: When other factors remain consistent, the voltage induced by a conducting substance moving across a magnetic field directly relates to the velocity of the fluid. An electromagnetic flowmeter measures the voltage to calculate the flow rate.

- Turbine: A turbine meter includes freely rotating propeller blades, positioned perpendicular to the direction the fluid is flowing in. By measuring the frequency of rotations, the turbine flowmeter can calculate the flow velocity.

- Paddlewheel: A paddlewheel flowmeter is similar to a turbine meter. In this case, as the paddlewheel turns due to the moving fluid, a sensor picks up on magnets in the paddle as it turns. These produce electrical pulses that indicate the flow rate.

- Ultrasonic: Ultrasonic flowmeters use transducers to send sound waves through a fluid. The returning sound wave can signal information about the fluid’s flow. This method only works on certain types of fluids.

There are other types of velocity flowmeters, as well. Each is best suited for a particular fluid, but they all manage to calculate velocity to determine flow rate.

3. Positive Displacement

Another common type of flowmeter is the positive displacement (PD) flowmeter. A PD flowmeter is the only type of flowmeter that determines the flow rate of a fluid by measuring the volume of fluid that comes through the meter, rather than measuring some other aspect of the fluid that relates to flow rate and calculating the flow rate based on that.

The meter contains rotating components that resemble mechanical cogs. The movement of the fluid through the meter causes these cogs to rotate. Unlike gears that fit tightly together, these rotating components trap small pockets of fluid in the space between them as they turn. The mechanism counts the rate of rotation of these components to keep track of how much fluid has passed through. This process works because the cogs’ rotational velocity links directly to the fluid’s flow rate.

The exact way a PD flowmeter measures the rate at which the rotating components turn can vary. One way is for the components to include magnets that trigger sensors outside the fluid chamber.

Positive displacement meters have a reputation for being extremely accurate. This accuracy is partly because their design accounts for nearly all the fluid that passes through. The margin for inaccuracy relates only to the tiny amount of fluid that manages to bypass the seal of the rotating components, sometimes called “slippage.”

In addition to being impressively accurate, PD flowmeters can handle a wide range of fluids when it comes to viscosity. A PD flowmeter may even be able to give a more accurate read for more viscous fluids, since they lend themselves less to slippage.

4. Mass Flow

A mass flowmeter, as the name suggests, measures the mass flow of fluid as it moves through a pipe. Mass flowmeters are common in the pharmaceutical, mining, wastewater, power and chemical and gas industries. These flowmeters are an ideal choice when you want to measure mass or when you’re working with a very viscous substance.

One popular means of measuring mass flow is by heating a section of fluid and noting the resulting change in temperature. A similar method is to keep a probe at a constant temperature and take note of how much energy the probe requires to do this.

Mass flowmeters that use heat to measure mass flow are called thermal dispersion flowmeters. Another common type of mass flowmeter is a Coriolis mass meter. Regardless of which method your meter uses to measure mass flow rate, you should note there is a difference in mass flow rate and volumetric flow rate.

Whereas a positive displacement flowmeter measures the volume of fluid that passes through, a mass flowmeter measures the mass of the fluid that travels through. A measure of volume would look something like cubic meters per second or another measurement of volume in a given amount of time. Mass is distinct from volume. You may see it measured by kilograms per second or a similar unit of measurement.

So, how can a measure of mass flow rate tell us the volumetric flow rate of a fluid? It turns out these measurements are related. By dividing the mass flow rate by the density of the fluid, a mass flowmeter can determine the flow rate in terms of volume. This process sounds fairly straightforward, but it can involve some extra steps to determine the actual density of the fluid, since it may vary depending on conditions.

5. Open Channel

Finally, there’s an open-channel flowmeter. This type of flowmeter includes a dam-like structure known as a primary device. Typically, the primary device is either a weir or a fume. We’ll look at the difference between these two types of devices in a moment.

If you know the relationship between depth and flow in your pipes, then by placing an obstruction in the pipe, the meter can take note of the difference in depth and use this information to calculate flow rate. The main difference between weirs and flumes is their shape.

Weirs are openings at the top of a dam, which can either be rectangular or V-shaped. As the water or other fluid flows over the dam, through the weir, the height of the fluid will increase. A greater increase in depth indicates a higher flow rate.

Flumes are similar to weirs, but they provide a constriction in width rather than height. As the fluid enters the narrower section of the channel, the water level changes which correlates to the flow rate.

In addition to playing a role in industrial applications such as wastewater treatment, open-channel flowmeters are a useful means of measuring the flow rate in free-flowing bodies of water such as streams and water.

How to Tell Your Flowmeter Has a Problem

Any flowmeter can experience problems, so you want to remain attuned to the readings your company’s flowmeter is providing and determine whether it’s operating consistently or may be having issues that are interfering with its ability to measure flow accurately.

If your flowmeter doesn’t seem to be working accurately from the outset, it’s likely due to improper installation. It could be that you need to reposition it to a section of piping that will deliver a more accurate reading. Or maybe the flowmeter’s calibration has been off since day one.

If your flowmeter has started to operate more erratically over time, you could have a maintenance issue. Sensors, flow lines and other components generally require some upkeep to continue to operate effectively over time. Be sure to pay attention to what sorts of maintenance tasks your company’s flowmeter calls for by carefully reading the manufacturer’s manual.

Each type of flowmeter is susceptible to various potential problems. For instance, electromagnetic flowmeters can experience issues if they get exposed to electrical detractors that interfere with the current. If you ever notice an indication that your flowmeter may not be operating accurately, have a service professional inspect it to diagnose the problem and offer solutions.

Flowmeter Maintenance From Global Electronic Services

There are many types of flowmeters, each of which offers various advantages and potential issues. The right flowmeter can help your company keep track of the flow rate of water, chemicals or any fluid that moves through your plant’s pipes. To ensure your flowmeter continues to deliver on its valuable purpose, be sure to address potential issues as soon as they arise.

Global Electronic Services can quickly provide you with a certified technician who has the expertise to repair your faulty flowmeter so you can maintain your operations. Learn more about our flowmeter repair services and contact us today.