Don’t Let Mechanical Failures Ruin Your Business

When running a manufacturing business or production line — regardless of whether it’s a single-outlet or multinational organization — mechanical failure is costly. Even a failure lasting only a few hours can cause huge productivity disruptions, which can lead to a loss of thousands of dollars — or more. You need to maintain every piece of equipment proactively to continue business and keep failures to a minimum. Here are six things you can do to help prevent machine breakdowns:

1. Lubrication is a must, not a choice

It’s simple: If you don’t keep oil in your vehicle, the engine is likely to seize, which can leave you in the middle of the highway. Equipment engines can also seize if you don’t keep your machinery lubricated. Machine reliability is dependent on proper lubrication. Don’t let one job fulfillment impact hundreds later by skipping scheduled maintenance. Set up a regular schedule and adhere to it strictly.

2. Inspection is a definite must, not an option

You need to keep a rigorous inspection schedule to detect any potential problems that could halt production. Look for improperly aligned parts, any fluid leaks — particularly hydraulic — and overheating, which can result in production line disruption. All three at once? … we won’t go there.

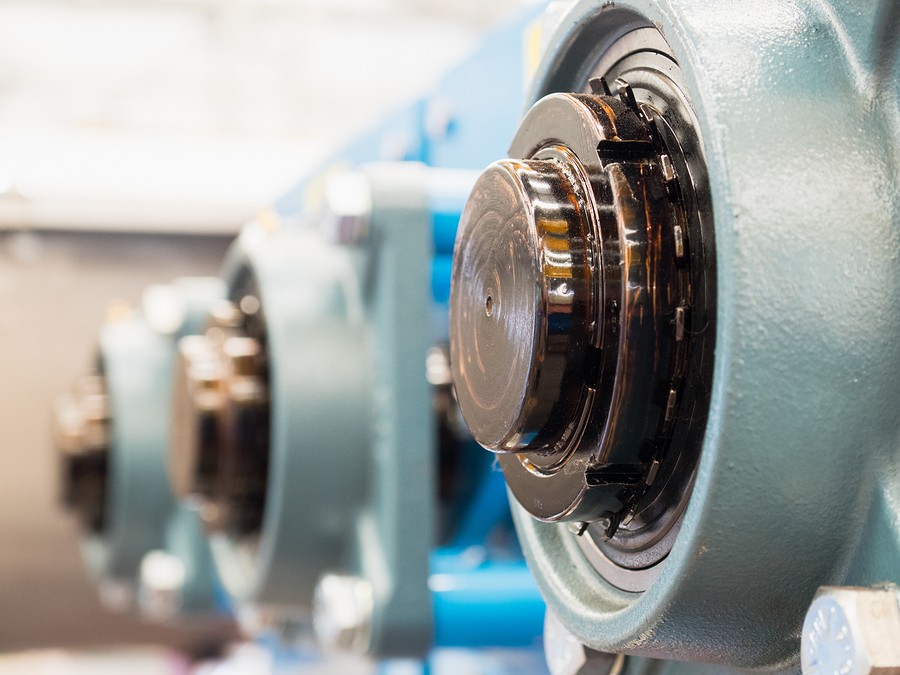

3. Bear down on bearings

Bearings are important machinery components as they help all the parts move sequentially. Should these parts get wet, they may begin to rust and start failing. If they’re overlubricated, other parts may start to move out of sync. Reviewing manufacturer requirements can help you maintain bearings or notify you when you should replace them.

4. Clean the air

Regular machinery cleaning doesn’t work if the surrounding air is dirty. Leaks, dirt, and dust can continually seep into machinery and cause failures even with proper maintenance. Ensure the production environment is dry and free of most humidity. If necessary, invest in an air purification system to eliminate a good portion of the dust and dirt in the environment.

5. Maintain maintenance

Keep a strict maintenance schedule to eliminate production outages. This is true even when you need to meet deadlines. It’s even truer when you need to meet deadlines because failure to check on machinery can cause such severe outages that you may never be able to meet deadlines.

6. Investigate the machine scene

CSI teams crawl over environments to discover the tiniest pieces of evidence, which they can use to determine causes of death or identify suspects. You need to complete the same intricate examinations when machinery requires repair — especially if a critical failure occurs. Problem causes may not be on the surface; issues may be hidden deep inside. Therefore, it’s necessary you perform extensive investigations.

It’s difficult to avoid mechanical failures completely, but you can keep your systems — and your bottom line — on the safe side when you perform regularly scheduled maintenance and know what to look for in your machines.

You don’t have to worry about recurring machine failures when you have help from Global Electronic Services professionals. We inspect entire machines and all parts as well as offer an 18-month warranty to ensure we fix your issues. Contact us or call [ab_phone] for your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs.

You don’t have to worry about recurring machine failures when you have help from Global Electronic Services professionals. We inspect entire machines and all parts as well as offer an 18-month warranty to ensure we fix your issues. Contact us or call [ab_phone] for your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs.