COVID and Staffing Challenges Have Forced a Robotics Renaissance in Manufacturing

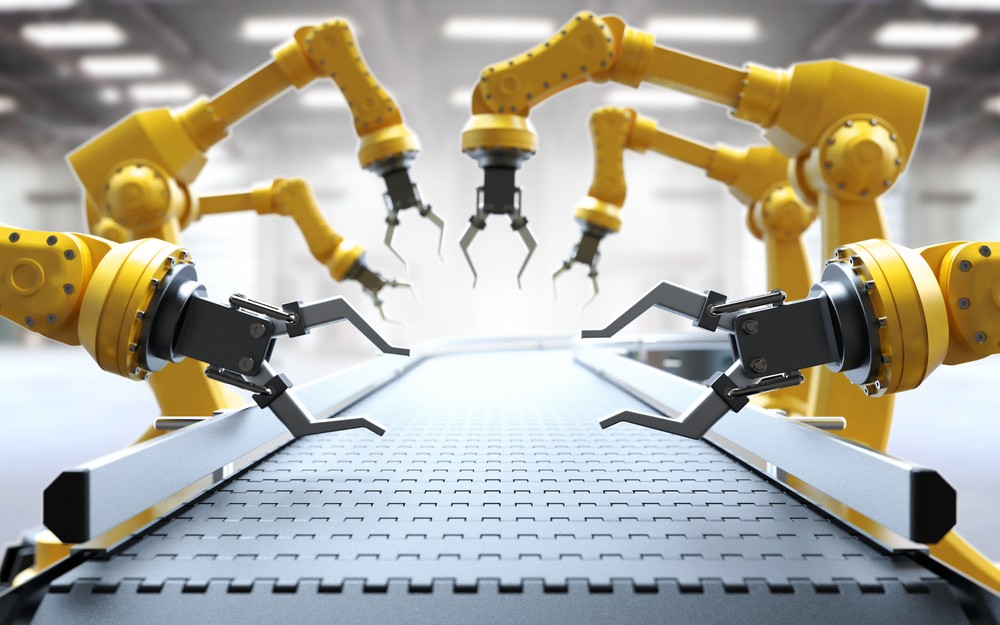

Robotics are a staple in manufacturing facilities across the spectrum of production. From autonomous robots to assistive co-bots, producers have come to rely on robotics to improve efficiency and production standards across the value stream. Now, post-pandemic, there’s renewed interest in the many opportunities that robotics offer. Analyst data indicates that where the robotics market might have plateaued before COVID, it’s surging after.

COVID’s impact on robotic investments

Before COVID, manufacturers were scaling down their robotic investments. While 2017 was a good year for the sector, weak consumer demand in both the automotive and electronics market, along with ongoing trade wars, caused a sharp decline in industrial robot demand for 2018 and 2019. Then, the pandemic hit.

The economic uncertainty of 2020, caused by production slow-downs and the shutdowns of factories and warehouses due to COVID, further disrupted the robotics industry. The sector bounced back in 2021, with industrial robotic shipments seeing a year-over-year increase of 31.9% as manufacturers searched for automation solutions to cover staffing shortages and other lingering effects of the pandemic.

A surging outlook for manufacturing robotics

The increased investment in industrial robotics shows no signs of slowing down, as a diverse range of industries look for ways to automate production lines. Everything from food producers to the shipping industry are embracing robotic technology, not because they want to replace human workers, but because there simply aren’t enough bodies to fill production lines.

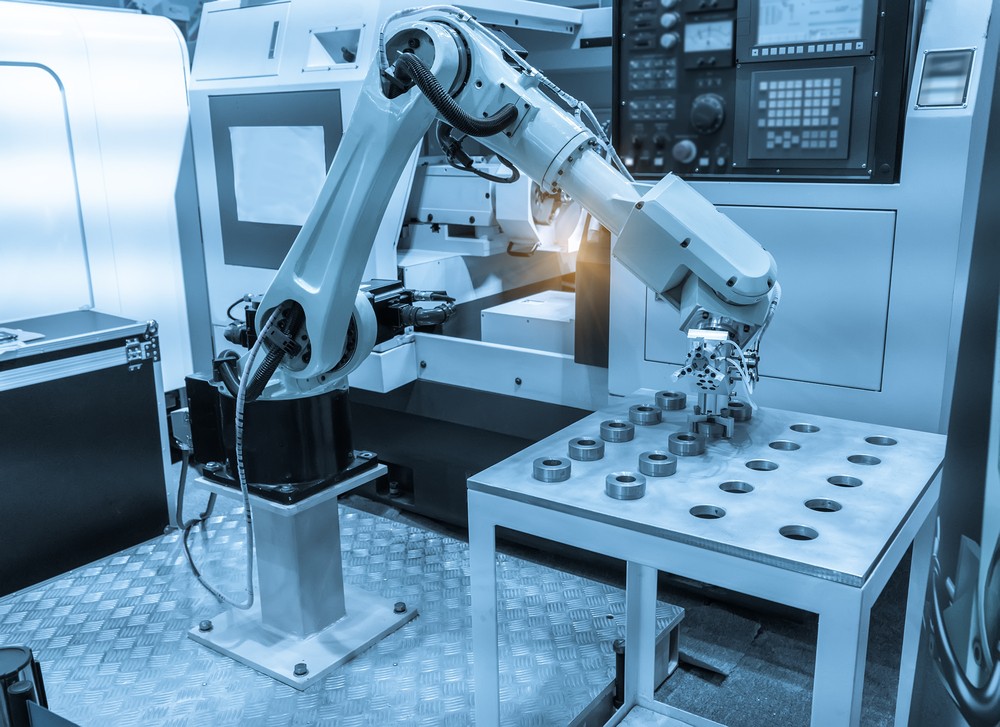

Manufacturing leaders are turning to robotics and automation to stay productive and competitive. With advancements in the Industrial Internet of Things (IIoT), powered by new 5G bandwidth, robotics is once again springing to the forefront of problem-solving initiatives.

The global industrial robot market was valued at $33.9 billion in 2021. Looking ahead, it’s likely to reach $61.09 billion by 2026, representing surging demand that could nearly double the market in just five years.

Robotics hold the key to continued innovation

The latest industrial revolution, Industry 4.0, has spurred continued innovation in robotics. From collaborative robots to artificial intelligence-enabled devices, underwater robotics to self-driving vehicles, new technologies are transforming production lines across manufacturing sectors. As the newest devices become cheaper, more mobile, and more autonomous, demand for industrial robotics is expected to rise, not just at home but also abroad.

As manufacturers across industries embrace automation to increase productivity, improve quality, and reduce errors — as well as boost worker safety — the global industrial robot market is set to nearly double in value by 2026. While there are still some challenges in the way of widespread robotics adoption, like large initial capital investments, privacy concerns, and safety issues, high-quality, innovative robotic technologies are here to stay. They’re giving manufacturers the cutting edge that helps them produce higher-quality products, for less.