As Pandemic Numbers Rise, Factories Need to Protect Themselves

The United States has officially topped 13.7 million cases of coronavirus, with new cases hitting record highs with each passing day — even breaching 200,000 in a single day (Nov. 20). It’s clear the situation is out of control. But that doesn’t mean it’s beyond trying. In fact, a little effort goes a long way in keeping people safe and transmission low.

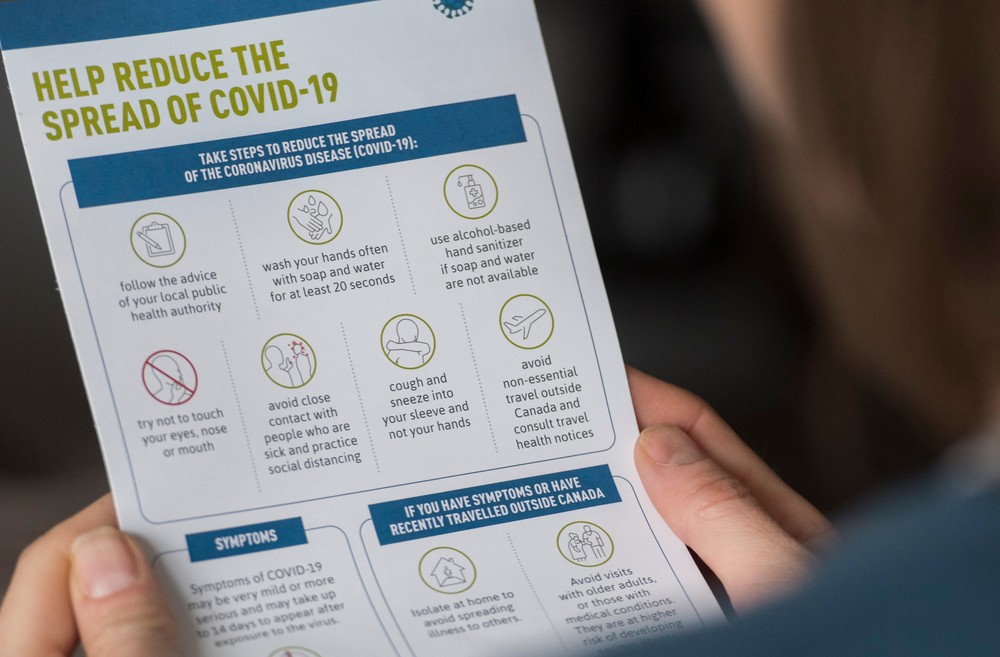

Following CDC (Centers for Disease Control and Prevention) guidelines is proven to reduce the rate of transmission and quell outbreaks, and it’s more important than ever to understand and follow these guidelines. Or, if you’re a manufacturer, to implement these safety standards for your workers, before your factory becomes the latest hotspot.

Essential and at-risk

Since the earliest days of the pandemic, manufacturers have been essential. Deemed essential workers, manufacturing technicians are on the front lines of turning out everything from personal protective equipment (PPE) and medical supplies, to essential consumer goods and products.

Factories can’t afford to close — for the sake of the company and the untold individuals relying on them for the products they produce. This makes factories both essential and at-risk. They can’t simply close their doors for 14 days and have employees quarantine, which means stopping the virus before it becomes prominent in the workplace.

Cases on the rise; the third ebb of the first wave

While there’s talk of the “third wave” of the pandemic, the fact is, the U.S. is really on the crest of the third ebb of the first wave. The pandemic was never really under control — only stunted. And it’s only going to get worse in the near-term.

The country is “rounding the corner into a disaster” according to professionals from the CDC and other health organizations. As the Thanksgiving holiday winds down, there’s an anticipated spike coming in the next 5-10 days, and new daily cases could double from their highs of today — in the 100,000s. This, as factory employees return to work to fight a pandemic that could very well affect them directly post-holiday.

Make safety a first priority

The coming surge in COVID-19 cases means two things for manufacturers: increased demand for essential production and increased risk of transmission in the workplace. Manufacturers need to act accordingly to maintain operations, while protecting workers. Doing so requires a strict safety-first approach and adherence to CDC guidelines and proven practices:

- Self-screenings and health evaluations before work

- Enforced social distancing on the factory floor

- Mask mandates and other PPE policies

- Contact tracing procedures and policies

- Enforced handwashing and sanitization

- Education about CDC recommendations

It comes down to putting a premium on safety. Don’t just have these policies; enforce them. Don’t just enforce them; educate employees on why they exist and how to observe them. Ongoing emphasis on the severity of the pandemic and the importance of the essential workforce needs to be a priority.

A factory can quickly become a coronavirus hotspot. It’s up to manufacturers to do everything they can to prevent this — especially as the country heads for another shutdown and essential workers become increasingly important.