8 Tips for Maintaining Industrial Motors During Hot Weather

As summer approaches and temperatures rise, industrial facilities face a unique challenge: keeping motors running efficiently. Excessive heat can wreak havoc on these essential components, leading to overheating, inefficiency, and even breakdowns. To avoid costly downtime and maintain peak production levels, here are eight key tips for maintaining industrial motors during hot weather.

1. Monitor motor temperature closely.

The first line of defense against heat-related motor problems is monitoring temperatures. Invest in noncontact thermometers for quick and easy temperature checks during routine inspections. Consult your motor’s manual for its recommended operating temperature range. If a motor consistently operates near or above its limit, investigate further to identify the cause and take corrective action.

2. Ensure proper ventilation and cooling.

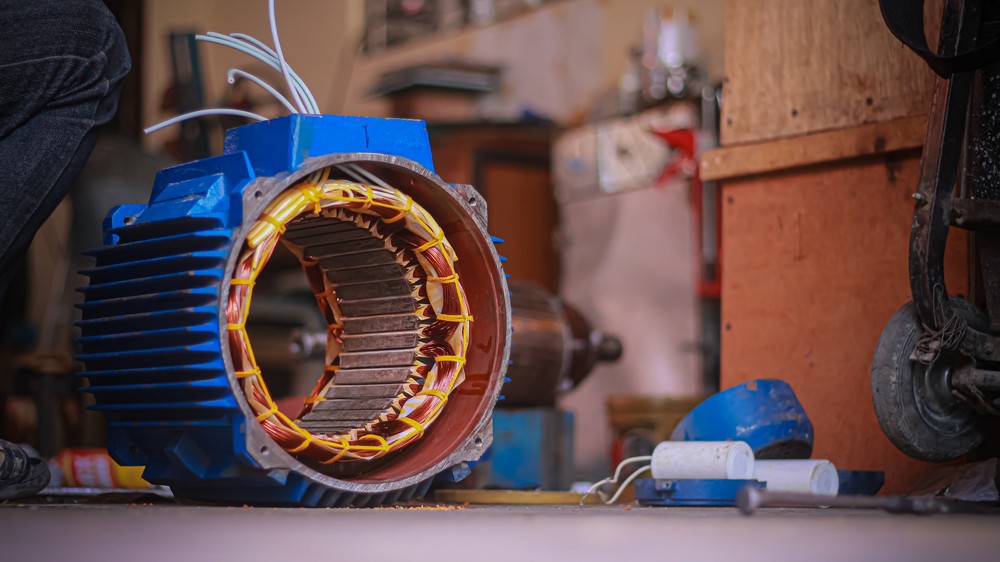

Heat dissipation is essential for motor health. Regularly inspect air intake vents and exhaust paths for any obstructions caused by dust, dirt, or debris. Clean clogged vents to ensure optimal airflow. For motors with built-in fans, verify that they are functioning properly and are free of any damage that could impede their rotation. In some cases, strategically placed auxiliary fans can be used to create additional airflow around the motor housing.

3. Schedule preventive maintenance.

Don’t wait for a motor to show signs of distress before taking action. Implement a preventive maintenance program that includes scheduled inspections of motor components like bearings and lubrication points. Inspect bearings for signs of wear or excessive vibration, and then relubricate them according to the manufacturer’s recommendations with the proper lubricant type. Early detection of potential issues allows for corrective measures to be taken before they snowball into major problems.

4. Optimize motor load.

Overloading a motor is a recipe for overheating. Ensure motors are sized appropriately for the application and are not consistently operating at or near their maximum capacity. If possible, redistribute workloads across multiple motors to reduce the strain on any single unit. Monitoring current draw can also help identify potential overloading situations.

5. Consider the ambient environment.

The surrounding environment can significantly impact motor temperature. If possible, relocate heat-sensitive motors to cooler areas within the facility. In situations where this isn’t feasible, explore options for installing heat shields or creating physical barriers to deflect radiant heat sources. Simple measures like keeping nearby equipment cool can also contribute to a more manageable thermal environment for your motors.

6. Upgrade lubrication.

During hot weather, consider switching to a higher-viscosity lubricant for critical motor components. Higher-viscosity lubricants offer a thicker film strength, providing better protection against friction and wear at elevated temperatures. Always consult your motor’s manual or the lubricant manufacturer for specific recommendations.

7. Invest in remote monitoring systems.

For critical motors or those operating in hard-to-reach locations, consider implementing remote monitoring systems. These systems can provide continuous temperature and vibration data, allowing you to proactively address potential issues before they escalate into major problems. Remote monitoring can also offer valuable insights into motor performance and efficiency, enabling you to optimize maintenance schedules and resources.

8. Train your staff.

Empower your staff with the knowledge to identify potential motor problems during everyday operations. Train them to recognize signs of overheating, such as unusual motor sounds or odors. Equip them with basic troubleshooting skills and encourage them to report any concerns to maintenance personnel promptly.

By following these tips, you can ensure your industrial motors remain cool and functional throughout the hottest summer months. Remember, a proactive approach to motor maintenance is key to preventing downtime and maintaining optimal production efficiency in your facility.