7 Questions To Ask Before Investing in IIoT Technology

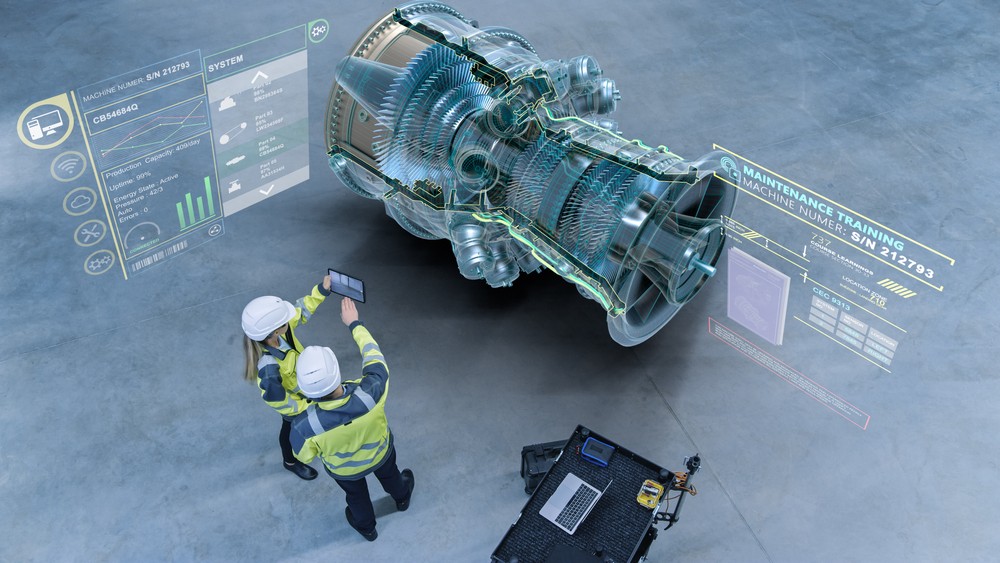

In the digital age of manufacturing, the Industrial Internet of Things (IIoT) is the glue binding a growing number of next-gen technologies together. IIoT technology is more accessible, and even smaller manufacturers are making progress with digitally connected operations. As manufacturers look to incorporate the IIoT into their facilities, they’re encountering questions they’ve never had to answer before.

Taking time to fully consider the situation is an essential step toward a sound investment. Ask yourself these seven critical questions before investing in IIoT technology for your factory.

1. What is the purpose of this IIoT investment?

Don’t invest in IIoT technologies because you think you need them. Define a clear and specific use case for any technology you plan to invest in, and make sure you can link the use case back to a need within your factory. Designate a specific factory purpose for any IIoT tech before making a move to invest.

2. What does the scope of integration look like?

There’s a big gap between determining why you need the IIoT and planning implementation. Once you’ve identified a specific purpose for the IIoT to improve your operations, figure out a clear strategy to implement tech solutions and create an integrated environment. Strategizing implementation will help ensure your investment is suited to your needs.

3. Who will manage implementation and integration?

Once you’ve nailed down the what, why, and how of an IIoT investment, start thinking about who. Who’s going to set up the IIoT in your manufacturing facility? Who will secure it? Manage it? Keep it updated? Decide whether technology management will be an in-house endeavor or if you’ll seek a service-level agreement with an external vendor.

4. How will you measure ROI?

The IIoT is an investment for manufacturers, and every investment should deliver a return to justify its upfront cost. Map out the path to ROI for your IIoT investment, and set clear, defined benchmarks for how you’ll achieve that return. This will be vital to building a business case that solicits buy-in from C-level executives.

5. How will you use the data produced by your IIoT investment?

The IIoT is all about facilitating access to data, so how will you use that data? Make a plan for leveraging the abundance of data generated by an IIoT network. Key areas of data application to consider include maintenance and reliability, safety, production, warehousing, and supply chain management.

6. What type of scalability does this solution offer?

Implementing the IIoT is a forward-looking process. Your digital network should scale as your company does and evolve along with your technology. You don’t need to have all the answers to make an initial investment, but it’s important to recognize your first IIoT solution as the first of many.

7. Do you have a plan to secure this technology?

This last question is the most important: How are you going to acquire the tech you need to build your IIoT? Do you have the funds? Stakeholder buy-in? Research which OEM or vendor is best positioned to help you, and make a thorough procurement plan as you move closer to making an investment.

There are dozens of questions every manufacturer should ask before diving headlong into an IIoT investment. Start with these seven core questions, and the path to a more digitally connected factory grows clearer with every answer.