Why Rewinding Isn’t Always Enough for Aging Motors

When a 20-year-old motor starts drawing excessive current or tripping breakers, most maintenance teams automatically think “rewinding.” The logic seems sound. Replace the damaged windings and insulation, and the motor should run like new, right? Unfortunately, the answer might not be so simple.

Motor rewinding only addresses one part of a complex machine. It restores electrical function but ignores the mechanical deterioration that happens alongside winding degradation. Too often, the product is a motor with fresh windings trapped inside an aging assembly that limits performance and shortens service life.

What rewinding addresses (and what it doesn’t)

Rewinding focuses entirely on the electrical components inside a motor while leaving everything else untouched. Understanding this distinction helps explain why some rewound motors perform well while others continue struggling with performance issues.

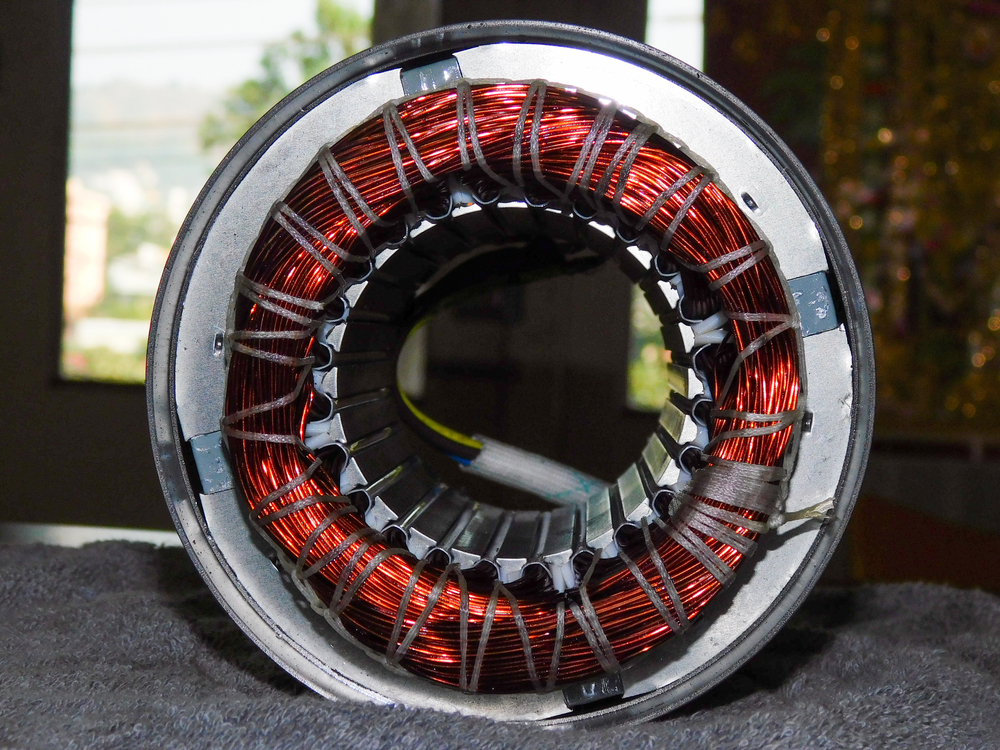

What rewinding fixes

Motor rewinding targets the electrical heart of the machine. Technicians strip out damaged copper windings and deteriorated insulation and then install new materials that meet original factory specifications. The process works well for motors suffering from ground faults, turn-to-turn shorts, or insulation breakdown — the electrical failures that cause excessive current draw and protective device trips. When done properly, rewinding delivers factory-level electrical performance at roughly one-third the cost of motor replacement.

What rewinding doesn’t address

Rewinding shops focus exclusively on electrical components and walk away once the windings test correctly. The mechanical assembly stays exactly as it arrived — complete with worn bearings that create vibration, shaft wear that prevents proper seal contact, and housing distortion from decades of thermal cycling. These mechanical problems continue to degrade performance and shorten service life even though the electrical system runs like new. It can be a wake-up call for facilities expecting renewed performance after rewinding.

Mechanical problems hiding in aging motors

What happens when a freshly rewound motor is at the mercy of mechanical components that continue to deteriorate? Here are some of the problems that develop gradually and often go unnoticed until they cause secondary damage or performance issues:

- Bearing deterioration and dynamic imbalance: Bearings develop internal clearances that allow shaft movement and create vibration. This vibration accelerates wear throughout the motor assembly and affects performance in connected equipment like pumps, fans, and conveyors.

- Shaft wear and sealing problems: Shaft surfaces develop grooves where seals make contact over years of operation. These worn areas prevent proper sealing even with new seals, leading to oil leakage and contamination that affects bearings and the newly rewound windings.

- Housing distortion and alignment issues: Mounting loads, thermal cycling, and vibration gradually distort motor frames over time. This distortion affects bearing alignment, creates internal clearance problems, and can cause rotor rub that damages mechanical components and fresh windings.

- Cooling system degradation: Air passages collect debris, cooling fans wear out, and thermal barriers deteriorate. Poor cooling affects winding life and overall motor performance, regardless of how well the electrical restoration was executed.

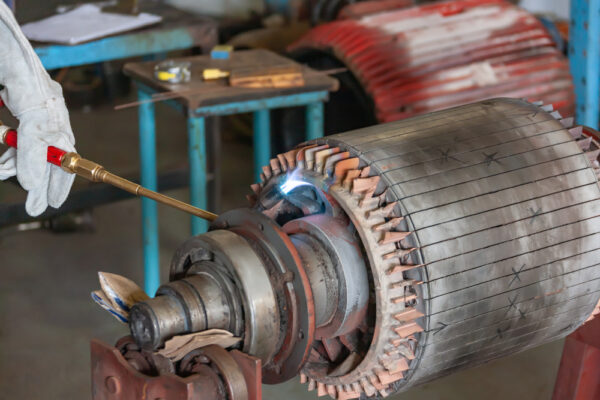

When does rebuilding deliver better value?

For aging motors that need a more comprehensive overhaul, rewinding falls short of what rebuilding can achieve. Where rewinding restores the electrical, rebuilding addresses everything. But when is it a viable option vs. replacement?

The economics of motor rebuilding come down to total costs over remaining service life. Motors needing multiple rewinds often cost more than comprehensive rebuilding that addresses all wear issues at once. Motor assessment determines the best approach. Minimal mechanical wear may justify rewinding alone, while significant bearing play or housing distortion calls for comprehensive rebuilding. Ultimately, it’s best to consult an expert like GES for a clearer picture of costs.

The complete picture matters

Rewinding serves an important role in motor maintenance, but it’s not a universal solution for aging motors. The facilities that get the best value from motor restoration are those that evaluate the complete machine rather than focusing solely on electrical problems. Motor restoration decisions affect equipment reliability, energy costs, and maintenance schedules for years to come. It’s worth making the right service call, not just the one that seems logical at the moment.