What is the Theory of Constraints?

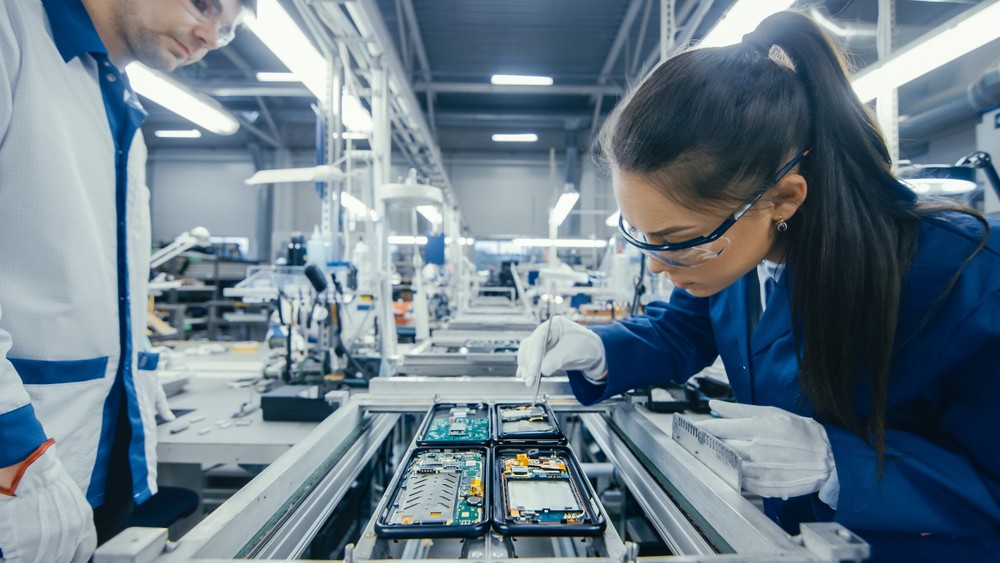

Every production process includes constraints. A machine can only produce X number of cycles per hour which caps throughput at Y number of units. This means Z revenue dollars per hour, per machine. These constraints dictate operations parameters and give manufacturers an understanding of what’s possible and what’s efficient.

But many manufacturers don’t understand the constraints at play within their different manufacturing processes. Luckily, they can consult the Theory of Constraints for a high focus understanding of what’s possible and where they can unlock more efficiency.

A core lean manufacturing concept

Manufacturers use the Theory of Constraints to identify obstacles preventing them from achieving certain goals: usually a bottleneck or some other inefficiency. The Theory of Constraints helps to find the “weak link” in the metaphorical chain of activity making up the manufacturing process. By identifying constraints, manufacturers can address the ability of a process to produce the desired result.

After identifying the inefficiency, manufacturers can develop systematic ways of improving operations to get rid of it and further improve processes and profits.

The five steps of the Theory of Constraints

One of the tools provided by the Theory of Constraints is a five-step process identifying and eliminating constraints. The five steps of this process include:

- Identifying the constraint. This involves identifying the part of a system causing the constraint. Specifically, it means rooting out the inefficiency weighing down the value stream.

- Exploiting the constraint. After identifying the constraint, technicians need to delve deeper into understanding it. Why is there an inefficiency, and how can techs address it to maximize its potential?

- Subordinating everything else. Technicians must next adjust the system to a setting for addressing the constraint. After this, evaluate the entire system and determine whether the constraint has disappeared or simply moved to another component. If the constraint is gone, skip step four.

- Elevating the constraint. If the constraint is still present, technicians should determine other viable options for elimination. Sometimes, this involves investing in major changes to the system.

- Identifying the next constraint. Manufacturers should constantly try to improve systems. After identifying and eliminating one constraint, move on to the next one. The result is progress toward the most productive system possible — one entirely free of constraints.

The complete Theory of Constraints is extremely involved and requires the work of skilled technicians, but properly educating staff members on the five core steps can help improve factory operations.

Why manufacturers use the Theory of Constraints

The Theory of Constraints is an effective tool for eliminating problematic areas within a production system. This can improve throughput of a product, increase productivity, reduce lead times, improve customer satisfaction, and increase profits. While the constraints themselves may be complex and varied, the Theory of Constraints is an effective, proven methodology for systematic approaches to mitigation.

Alleviate constraints to improve throughput

Constraints are symbolic of the rules governing manufacturing value streams. But, like any rules, there are ways to stress, and even circumvent them, and create better outcomes. Using the Theory of Constraints to identify inefficiencies within a specific process, value stream, or operation, manufacturers can glean a better understanding of how to approach improvements.

Finding ways to alleviate — or even eliminate — constraints is key to improving efficiency and productivity.