The Usual Suspect – How a Common Failure Component Can Get a Bad Rap

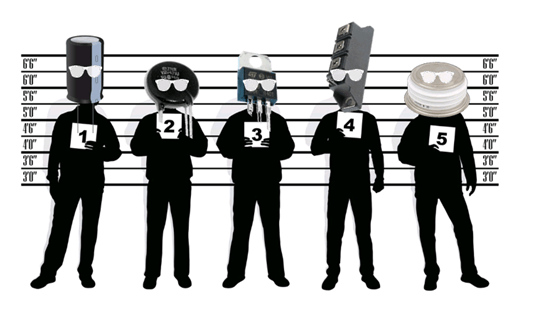

In the world of DC motor controls, SCR’s (Silicon Controlled Rectifier, a trade name invented by General Electric) have always had a bad reputation. I have never really understood why; they are typically very dependable. Often I have seen customers change them out as a first response to a failure when some other components and or wiring was the true cause of the problem. In fact, in the troubleshooting section of a lot of older drive manuals, customers are instructed to change them in response to any sort of output issues (not as common nowadays as OEMS typically steer their customers away from performing their own repairs) .

SCRs of course are not immune to failure but are very rugged in their construction. An SCR is a Silicone Controlled Rectifier, basically a diode that has to be turned on to enable current flow. And like a diode the current will only flow only in one direction. Also the SCR will remain on as long as current is flowing in the correct direction. SCR’s have long been used in DC motor controls and power supplies because of those properties.

To understand the SCR as a component, you must first understand why they are used. You see, the power coming into our homes and factories is AC (alternating current). The defining property of AC current is th at the flow switches direction many times a second depending on the speed of the generator distributing the power (60 HZ in the US, 50 HZ in some places overseas). The reason the power companies transmit AC power as opposed to DC is that:

at the flow switches direction many times a second depending on the speed of the generator distributing the power (60 HZ in the US, 50 HZ in some places overseas). The reason the power companies transmit AC power as opposed to DC is that:

- AC current travels easier over long distances

- AC current is much more efficient to step down using transformers to something useable as opposed to DC

The job of the SCR is to produce the DC voltage, (from the AC entering the SCR), to run the DC motor with a calculated ramp time. The current to the motor can only flow when the SCR is turned on and current is in one direction. That is why we use SCR’s in most DC drives. The drive generates a gate signal to turn on the SCR with a specific frequency and depending on when it is turned on with reference to the incoming line phase angle we determine how much current is going to flow. Knowing this, it is easy to see why the SCR would be a common failure component. It will come into contact with any stress caused by both incoming power and output load issues. But for the same reasons, SCR’s chosen in most motor control applications are picked to be able to withstand many times the drive and motor’s rated capacity. In other words SCR’s don’t typically go bad on their own. When trouble shooting any repair it is good to look for the common things, but do not let that narrow your vision. I see a lot of new techs pull their hair out again and again with misdiagnosed SCR failures. But in fact SCR failures without a related cause is actually much more rare than is commonly believed. It is better to make the common failure component the start of the investigation, rather than the usual suspect. In my book, the SCR is Innocent until proven guilty.

Please share your comments or questions with us below and be sure to visit gesrepair.com or call us at 1-877-249-1701 to learn more about our repair services. We’re proud to offer Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page, Like Us on Facebook! Thank you!