How to Use a Fishbone Diagram the Right Way

Without understanding the root cause of a problem, it’s impossible to fix it. Root-cause analysis is one of the foremost concepts in Lean manufacturing, with several methods for assessing root cause — including the fishbone diagram. But root-cause analysis is only as good as the approach, however, which means understanding how to use a fishbone diagram accurately. Used properly, it’s a powerful tool; used incorrectly, you might only end up addressing symptoms, not the root cause.

Familiarize yourself with the fishbone

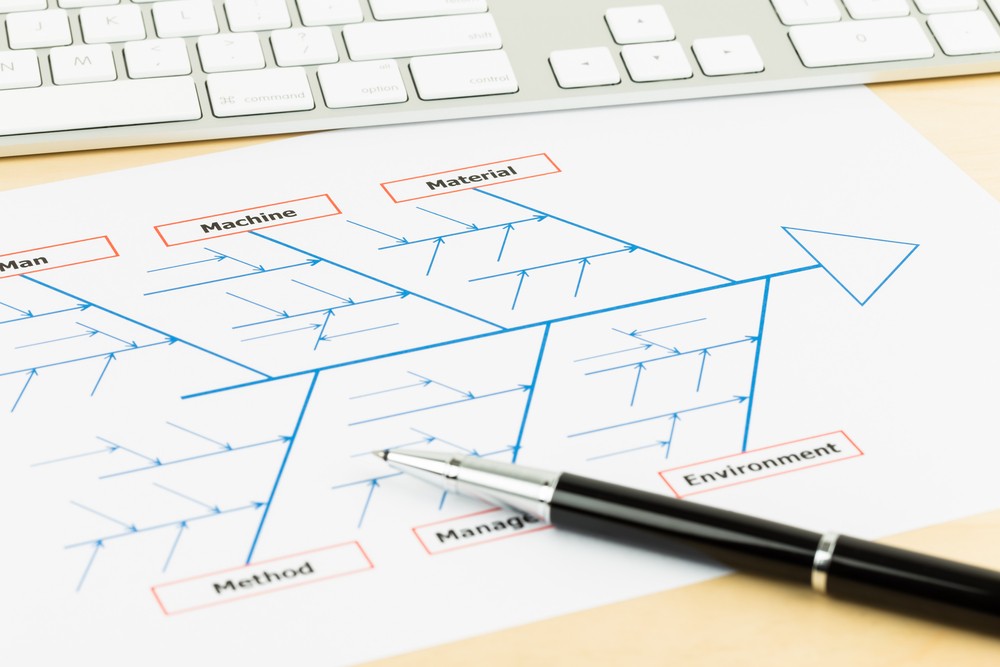

A fishbone diagram — also called an Ishikawa diagram, named for its inventor, Professor Kaoru Ishikawa of Tokyo University — is a simple concept. The problem is the “head of the fish,” with symptoms branching off from the “spine,” classified by the nature of each. The result looks, as you might imagine, like a fish skeleton.

The reason many manufacturers use a fishbone diagram is because it’s intuitive. It forces you to ask questions and make observations, then categorize that information. Anyone can use a fishbone diagram, which makes it a practical tool on the factory floor. Simple. Effective. Enlightening. Fishbone diagrams are a tool worth using.

The challenges with fishbone diagrams

Fishbone diagrams are an evaluative tool. Unfortunately, many people see them as a driver of solutions, leading them to use the diagram incorrectly. The idea is to find a confluence of issues that illuminate the full scope of a problem, not take the symptoms at face value.

Think of a fishbone diagram as a constant progression of the question “why.” The electric motor has stopped working. Why? Because the windings have gone bad. Why? Because they’re underserviced. Why? Because the service schedule wasn’t followed. Why? And so on, and so forth, until you no long have an answer. This process repeats for every symptom of an issue (e.g., the motors bearings weren’t properly lubricated, the power casing was corroded). Every individual symptom is met with “why” to better understand how it came to be.

The issue is, most people take the symptoms of a fishbone diagram at face value and thus, don’t maximize it. The electric motor is dead because the windings are bad. Instead of asking “why,” they replace the windings. But what if there’s a fault that goes deeper? What if the windings go bad again in just a few weeks? Was the problem really solved? This is an improper use of a fishbone diagram.

How to use a fishbone diagram properly

Using a fishbone diagram is simple when done correctly. While the objective is to keep asking “why” to get to the root cause of individual symptoms, it’s also important to structure the diagram accordingly. In a manufacturing setting, that means splitting the “bones” of the diagram into six factors: machine, method, material, manpower, measurement, and milieu (environment).

Categorize each issue present into one of these segments and trace it back as far as possible by asking “why.” The final result should look like a fish skeleton, with the main problem (effect) at the head, and numerous branching variables. As you begin to get to the root cause of each variable or symptom, you get avenues for investigation. When you can no longer answer “why,” you’ve used the diagram correctly and stumbled onto an opportunity for improvement in regard to the root cause.