How Artificial Intelligence Is Transforming Manufacturing Operations

The artificial intelligence boom is here, heralded by technologies like ChatGPT and Midjourney. And while AI platforms currently focus on creative and clerical work, they’re rapidly expanding into other spaces — manufacturing included. As producers think about investing in technology, they increasingly need to consider how AI might help them improve operations.

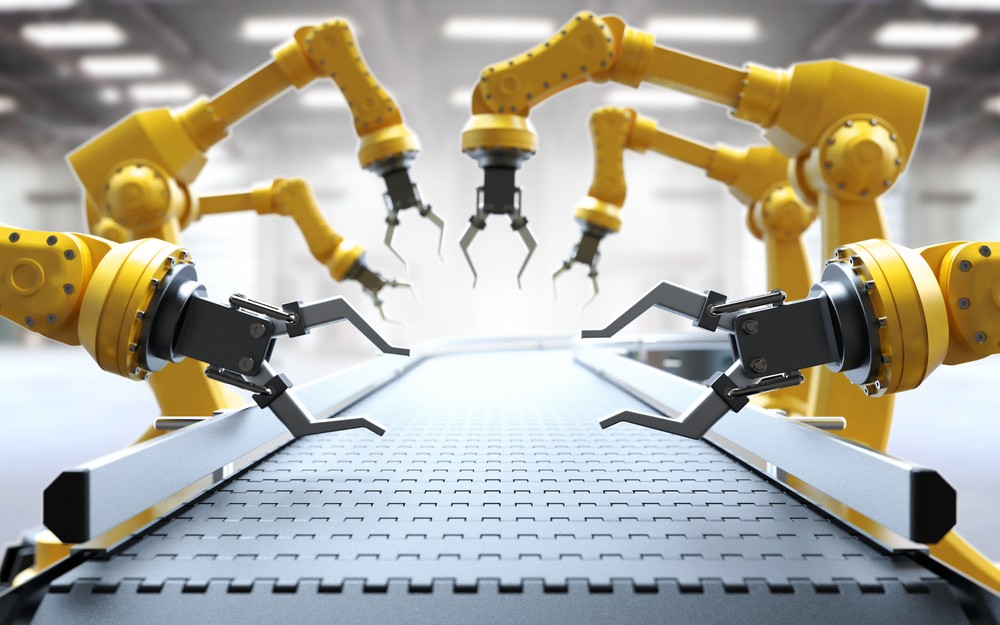

AI leads to automation

The rapidly growing field of artificial intelligence focuses on getting computers to think and learn like humans. AI allows computers to solve problems without human direction by recognizing patterns and making decisions based on established rules, frameworks, and parameters. As a result, AI algorithms process massive amounts of data much more quickly than any person could and can identify patterns not obvious to humans.

This type of automation is what makes things like facial recognition software and self-driving cars possible. As robots become increasingly better than humans at completing routine tasks with more complexity and efficiency, fewer hours will be worked — with more results achieved from the time spent.

AI use cases in manufacturing

AI is already helping manufacturers do what they do better, faster, and cheaper — and we’re only scratching the surface. Here’s a look at some of the best AI use cases for manufacturing:

- Robotic process automation for repeatable tasks: AI is well suited for robotic process automation (RPA), enabling machines to autonomously handle repetitive tasks, boost productivity, and improve efficiency.

- Digital twins to model production and performance: Digital twins allow companies to model how production lines are running by taking data from multiple sources to monitor and control various systems throughout the plant.

- Predictive maintenance models evolving over time: Through predictive maintenance models, AI can detect when a machine may need attention to avoid unwanted surprises and costly repairs.

- Demand-predictive models to help manage push-pull: AI-supported demand-predictive models provide manufacturers with insights into their future customer base and inventory level trends, helping them manage how much inventory is “pushed” onto the market and how quickly it can be “pulled” when the need arises.

- Auto-detection for faults, failures, and defects: AI technology enables automated detection of faults, failures, or defects during the quality-control process, ensuring products meet industry standards before coming to market.

- Rapid modeling and prototyping for speed to market: Using AI’s “learning” capabilities, companies can quickly develop operational models without sacrificing accuracy or compliance. This has the ability to reduce time to market while elevating product quality.

AI in manufacturing is evolving rapidly

The future of manufacturing is here. AI technology is rapidly evolving, allowing manufacturers to experiment and stay ahead of emerging trends. Increased automation through artificial intelligence opens a world of possibilities for businesses looking to maximize efficiency and improve processes.

With a labor shortage and growing skills gap, it’s now more critical for manufacturers to explore, experiment, and invest in automation solutions. Keeping ahead of the emerging trends in AI is the clear answer to remaining competitive in today’s challenging economic climate.