4 Major Signs of IGBT Module Failures

When an IGBT fails, it rarely does so quietly. Maybe the motor jitters, or the entire drive trips without warning. Maybe it works — just enough to mislead you — until the next power cycle brings it down again. Either way, insulated-gate bipolar transistors (IGBTs) don’t last forever. They’re built to switch fast, switch clean, and handle the thermal load. But over time, heat, stress, and poor connections take a toll.

So how do you know when a fault is forming? Here’s how to spot a failing IGBT module before it turns into a bigger problem:

1. Erratic switching or blown fuses

The most obvious sign something’s wrong with an IGBT is when it no longer switches properly. Either it stops switching when it should, or it stays stuck on, flooding the circuit and damaging other components. If a fuse blows the moment power is applied, a shorted IGBT might be to blame. Look for these red flags in your diagnostics:

- The drive won’t start or shuts down at startup.

- Output phases show a dead short to ground or DC bus.

- Fuses blow repeatedly, even after replacements.

- Oscilloscope traces reveal irregular switching pulses.

2. Excessive heat buildup — even under normal loads

IGBTs are built to handle heat, but only up to a point. Once internal junction temperatures exceed their design limits, performance degrades fast. What starts as a little extra warmth can quickly snowball into a full thermal breakdown. When one IGBT runs hotter than the rest, it’s often the first to fail. And once one fails, the others are rarely far behind. Check for temperature-related symptoms like:

- Heatsinks feel hot to the touch, even under light load.

- Built-in temperature sensors trip early or trigger shutdowns.

- You notice a slow decline in performance after power-up.

- Adjacent components show signs of thermal stress or discoloration.

3. Unbalanced output or phantom motor behavior

IGBTs don’t just switch current — they shape it. So, when they begin to fail, the symptoms show up in your output waveform. What you’ll get is a jittery motor, a humming drive, or a total mismatch in expected speed versus actual output. You might notice:

- The motor stutters or vibrates under load.

- Output waveforms lose symmetry or become distorted.

- Motor RPM doesn’t match commanded speed.

- Unusual harmonics appear in the power trace.

Trust the experts in electrical repair

GES knows what to look for when IGBT modules begin to fail. Send in your ABB modules for diagnostics and repair today and you’ll get 10% OFF single repairs or 15% OFF 3+ repairs now through the end of the month!

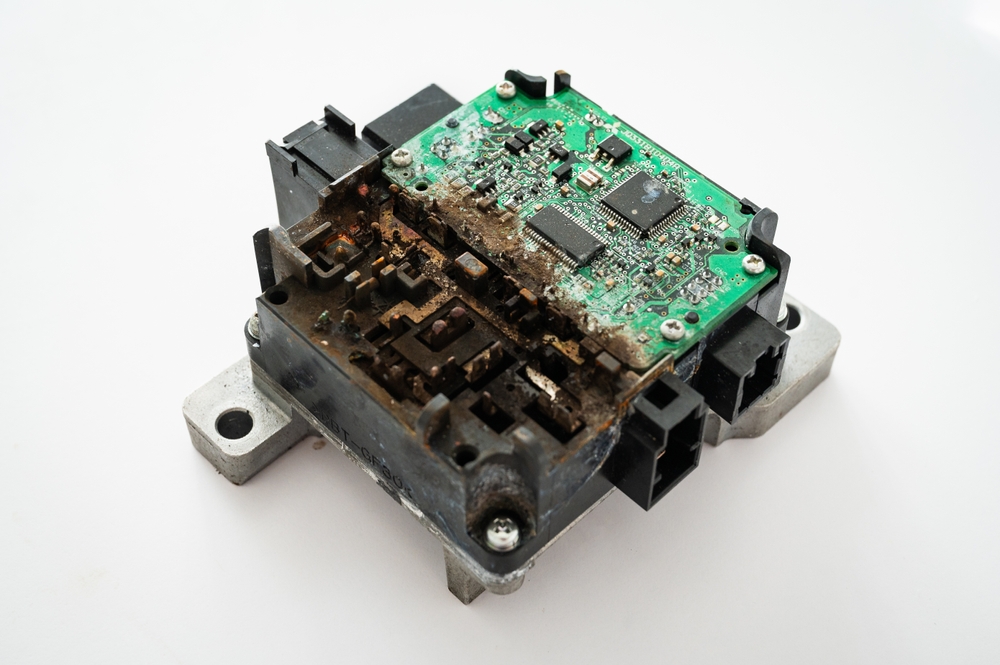

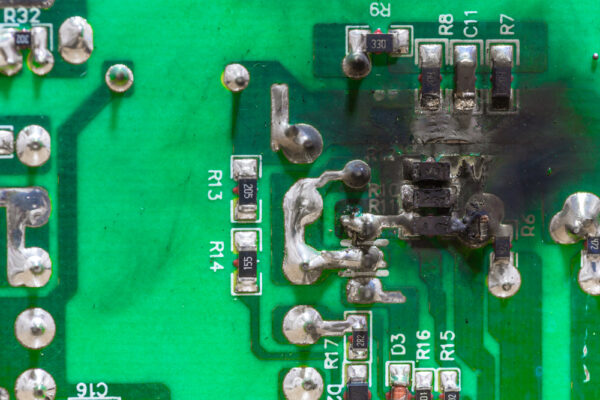

4. Physical signs of fatigue or failure

When in doubt, pull the module and inspect it. Physical wear and damage often tell a clear story. If the IGBT casing shows signs of bulging, cracking, or burnt areas, internal failure is already well underway. Some of these issues stem from old age. Others point to larger issues — like voltage spikes, poor heatsink contact, or overloads. Either way, once you see physical damage, that IGBT’s done. Watch for these telltale signs:

- Charred board traces or soot near the IGBT terminals.

- Cracks or separation in thermal compound or solder joints.

- Swollen or discolored casing.

- Burn marks where the collector or emitter connects.

Failures that fly under the radar still do damage

Not all IGBT failures are obvious. Sometimes the fault lies in the gate drive circuitry, not the IGBT itself. Sometimes the failure is intermittent, triggered only under high switching frequency or fast deceleration. Diagnosing it takes time — and the right tools. Don’t leave things to chance, especially when hidden faults can damage more than just the drive. Observe the signs, act fast, and give your IGBTs the attention they deserve.